Santa Paula, CA, – Abrisa Industrial Coatings (AIG) a division of Abrisa Technologies, a HEF Company has broadened their scope of capabilities being offered via their Precision XY Saw Cutting services utilizing processes originally developed for semiconductor wafer dicing.

Santa Paula, CA, – Abrisa Industrial Coatings (AIG) a division of Abrisa Technologies, a HEF Company has broadened their scope of capabilities being offered via their Precision XY Saw Cutting services utilizing processes originally developed for semiconductor wafer dicing.

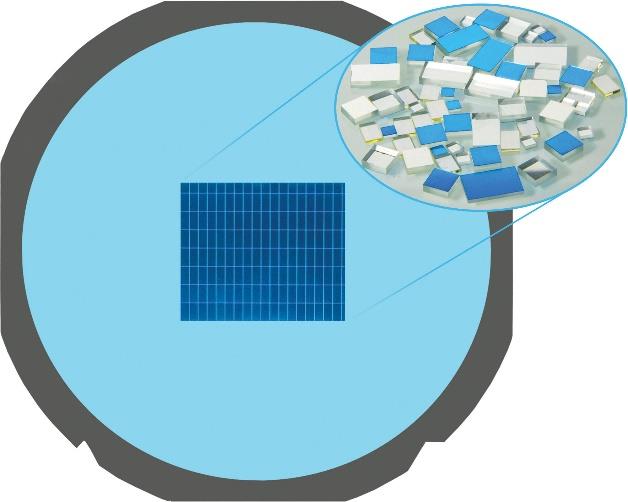

A camera assisted array cutting method is used to precisely align a workpiece parallel to the blade to ensure accurate cutting down the middle of each street. The tolerance can be as tight as ±0.001” (0.025 mm). This cutting method is ideal when parts are rectangular and volumes high as well as when parts are small or when parts require XY dimensional tolerances such as 0.025 mm with consistent perpendicularity of edges to faces is needed. Camera assist can also use fiduciaries, notches, flats, and matched corners as the precision locating feature. This process is key when small optical components must be fit/press fit, or hermetically sealed and in need of low cosmetic, chip free defects and a near “100%” coated clear aperture for imaging, sensing, laser beam steering, indicators, and sighting.

Edges generated by the saw cutting/dicing process have a ground finish, making them well suited for epoxy bonding. Other features as steps, grooves, channels, and mini mounting “flanges” can also be generated using this saw cutting process of vinylized glass patties.

According to Susan Hirst, General Manager for Abrisa Technologies, “Popular technical and specialty materials processed include coated and uncoated glass, glass wafers, filter glass, rods, acrylic, and optically bonded structures as thin as 0.2mm up to 5 mm in thickness and an overall dimension up to 6.5” square. Additionally, groove or channel cutting is available from 0.010” to 0.080.”

Abrisa Technologies, a premiere Total Solution specialty glass fabrication and Optical Coatings provider, offers a vast selection of cut-to-order coated materials, uncoated technology glass, and custom coating services for a host of optics applications which can also be performed on (CFM) customer furnished material.