Corning® Gorilla® Glass

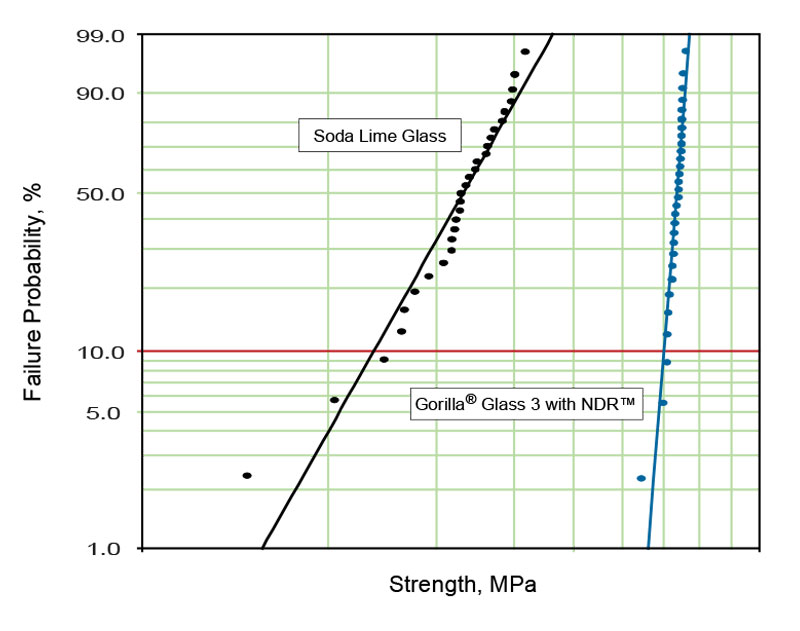

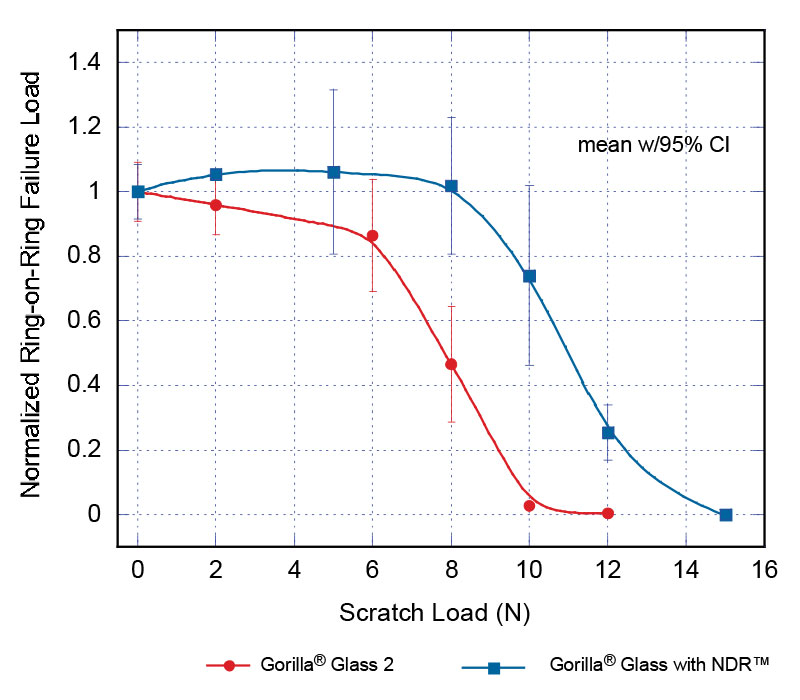

Abrisa Technologies custom fabricates and provides optical coatings on Corning’s Gorilla® Glass 3 with Native Damage Resistance™, an alkali-aluminosilicate thin sheet glass that is better able to survive the real-world events that most commonly cause glass failure. With its new core composition, this glass enables improved damage resistance and toughness by helping to prevent the deep chips and scratches that cause glass to break.

Features

- Corning® Gorilla® Glass superior composition allows a deep layer of chemical strengthening than is possible with most other chemically strengthened glasses, making it more durable and more damage resistant

- Abrisa Technologies can strengthen, fabricate, screen print and optically coat Corning® Gorilla® Glass

- Abrisa Technologies can apply anti-reflection optical coatings, ITO coatings and Oleophobic coatings on Corning® Gorilla® Glass

- Glass designed with improved native damage resistance

- Enhances retained strength after use

- High resistance to scratch and sharp contact damage

- Superior surface quality

Applications

- Ideal protective cover for electronic displays in:

- Smartphones

- Laptop and tablet computer screens

- Mobile devices

- Touchscreen devices

- Optical components

- High strength glass articles

- Protective cover glass

- Handheld devices

- Avionics and defense

- Instrumentation

- Ruggedized display

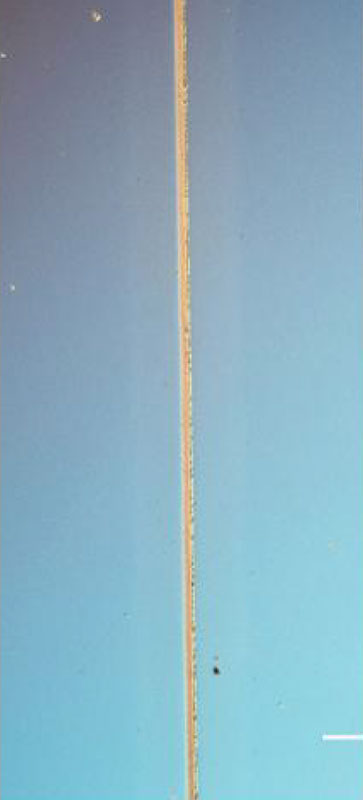

Knoop Visual Scratch Test

After Ion Exchange

Thicknesses

- 0.4 mm

- 0.55 mm

- 0.8 mm

- 1.1 mm

- 1.5 mm

- 2.0 mm

Chemical Strengthening

Properties

Viscosity

Optical

* Core index is used for FSM-based measurements since it is unaffected by ion-exchange conditions.

Chemical Durability

Durability is measured via weight loss per surface area after immersion in the solvents shown below. Values are highly dependent upon actual testing conditions. Data reported is for Cornings Gorilla Glass 3 with NDR™.

Electrical Properties

Terminated coaxial line similar to that outlined in NIST Technical Notes 1520 and 1355-R.