PRO-HC-VIS1 Anti-Abrasion Hard Coat Clear Glass

POS Scanners ● Passport & Transit Pass Readers ● Field-Use

Abrisa Technologies now offers PRO-HC-VIS1, a protective anti-abrasion hard coat clear glass coating option for high traffic contact scanner applications which delivers up to 40X more linear taber abrasion resistance when compared to uncoated glass and HIE™ chemically strengthened glass surfaces.

Scanner beds experience abrasion damage from produce/product packaging, cell phones, keys, baskets, dirt, and debris and other items that are dragged across or in physical contact with them. Over time, damage results in the development of haze which clouds the glass and leads to a failure to read or capture data, QR, barcodes, and images required for purchase transactions or Identity verification. This is of particular concern for (POS) Point-of-Sale contact scanners, airport or mass transit “ticket” scanner/readers where replacement and maintenance is not only inconvenient, but downtime impacts critical passenger traffic flow or purchase transaction capacity.

Features

PRO-HC-VIS1 coating can be applied to a wide range of Abrisa Technologies’ materials:

- Low Iron Soda Lime & SCHOTT Borofloat®

- Non-Glare & Anti-Reflection Coated Glass

- HIE™ Aluminosilicate Strengthened Glass

- Custom Coated Technical or Specialty Glass

Performance

- Transparent to Eye, Camera, Diode

- 20-40X Enhanced Wear Resistance

- 100-400X Enhanced Resistance to Sand

- -40° to 70°C: Industrial, Outdoor, Freezer

- Format Sizes from mm’s to 16” x 23”

- Easy-to-Clean & Sanitize Surfaces

Applications

- Point-of-Sale (POS) Contact Scanners

- Passport & Document Scanners/Readers

- Mass Transit “Pass” Scanners/Readers

- Signature Transaction/Document Pads

- Industrial Machine Vision Parts Inspection

- Parcel & Package Scanners/Readers

- Ruggedized Defense Transparencies

PRO-HC-VIS1 Anti-Abrasion Hard Coat Clear Glass coating provides a highly abrasion resistant surface capable of maintaining clarity through tens of thousands of successful scanning events for high device uptime hours.

PRO-HC-VIS1 can be applied to a large selection of Abrisa Technologies’ specialty glass substrates.

Options:

- 1 or 2 Sides Coated. Glass as Thin as 2.0mm ***

- Standard, HIE™ Strengthened or Heat Toughened Glass

- Standard Anti-Reflection & Non-Glare on Side 2

- Screen Printing, On-Demand Laser Graphics & Identifiers

- Custom Optical Coatings on Side 2

- Applied Safety Film, Gaskets, or Other Films on Side 2

*** 1.0mm upon special request

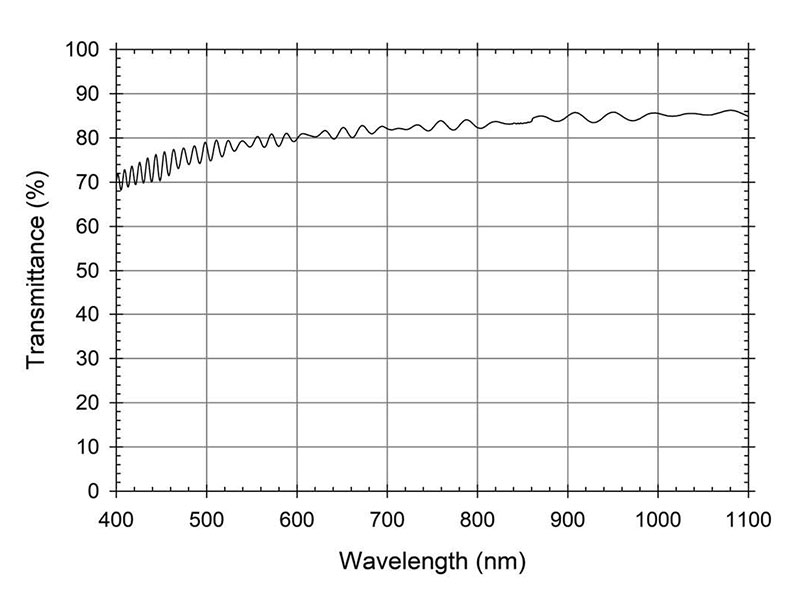

Clarity & Transparency from 400-1000nm

- Cameras, Sensors, VIS/NIR Lasers, Humans

Damage Resistance and Haze

- Enhanced Abrasion Resistance*

- 20-40X Reduced Haze vs Uncoated Glass/HIE™ Aluminosilicates

- Enhanced Resistance to Sand**

- 100-400X Reduced Haze vs. Uncoated Glass/HIE™ Aluminosilicates

* 10K Cycles Coated, 1K Cycles Uncoated – Linear Taber

**ASTM D968 Falling Sand