Neutral Density Filter Coatings & Dark Mirrors

There are some applications for which the light used is too intense. In those cases a filter is often needed to apply a reduction in the intensity of the light without influencing the spectral profile. These wavelength neutral filters are often specified in terms of their optical density. Optical density can be calculated by taking the negative of the log (base 10) of the transmittance. For example, an optical density of 0.5 would be equivalent to approximately 32% transmittance. An optical density of 1.0 would be equivalent to a transmittance of 10%. Standard neutral density filter designs are available for the UV, Visible, and IR bands and for a variety of optical density values.

A similar optically significant case involves surfaces for which reflectance and transmittance are required to both be minimized over a narrow or broadband spectrum. This type of coating is commonly called a Dark Mirror due to the black non-reflective appearance. Dark mirror coatings are often used to reduce stray light reflections at surfaces intended to be opaque. A dark mirror coating can be applied to a variety of glass and metal substrate materials.

Specifications

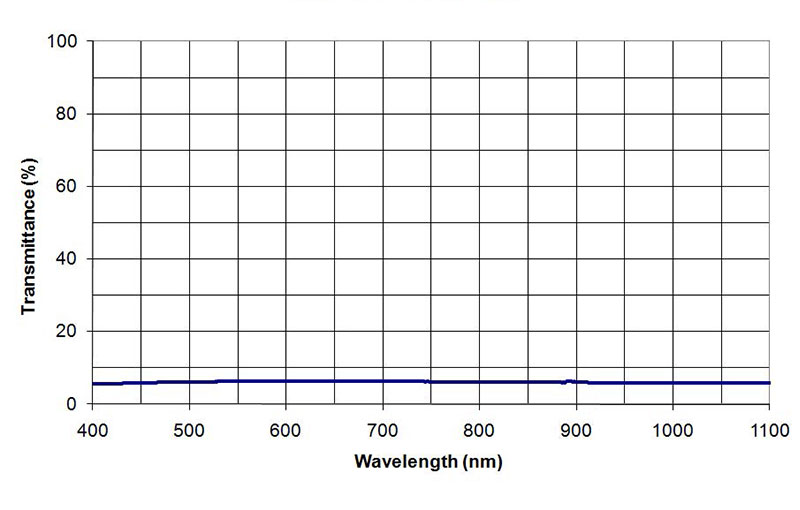

Neutral Density Filter

This neutral density filter example has an optical density of approximately 1.2 and a band average transmittance of 6.25 ±1.25% for wavelengths 400-1100nm.Standard neutral density filter designs are also available for 12.5%, 25%, and 50% transmittance.

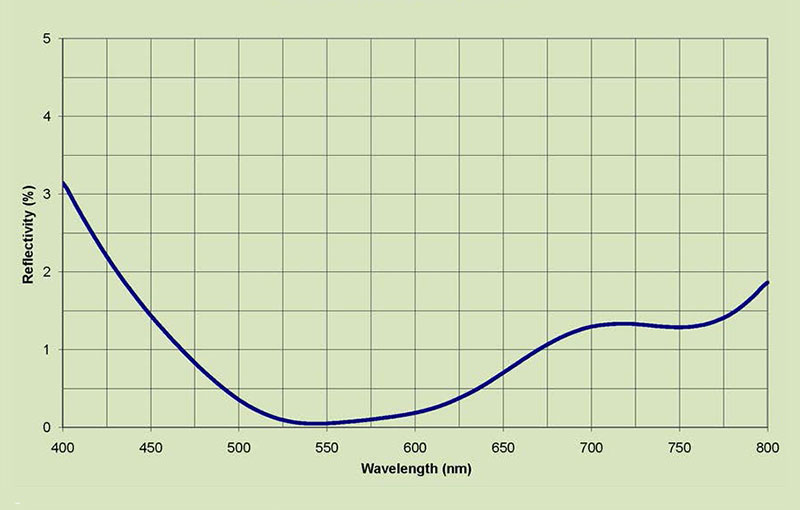

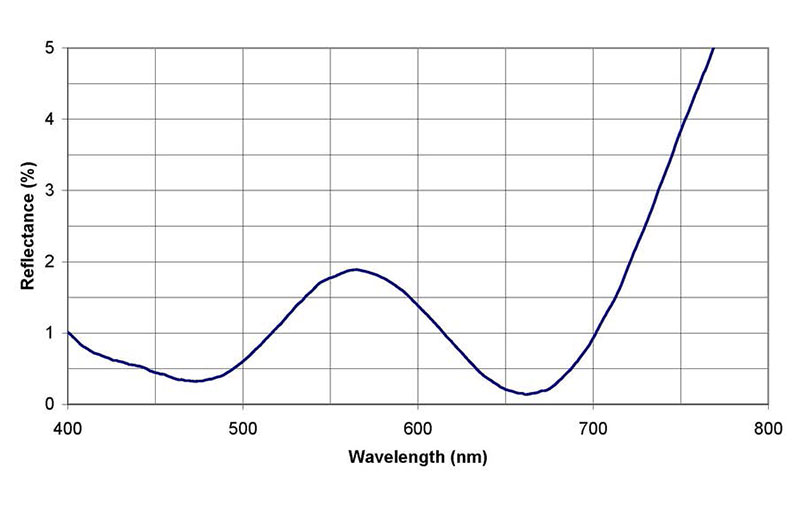

Dark Mirrors

It can be useful to separate Dark Mirror coatings into two groups: Front Surface and Back Surface. A front surface dark mirror design is one for which the reflectance is intended to be very low when viewed from the side coated. In contrast a back surface dark mirror design is intended to be viewed through the glass substrate. It is helpful to remember that a front surface dark mirror may be moderately or highly reflective when viewed from the back surface. And similarly a back surface dark mirror design may be quite reflective when viewed from the front surface.

You may have read the paragraph above and thought, “But wait! My application requires a dark mirror that has low reflectance for both the front and the back!” If so, we are glad to say you are in luck. ZC&R has extensive experience designing dark mirrors that can be used in both configurations simultaneously. This type of dark mirror allows your optic to be both opaque and dark when viewed from either side. Whatever type of dark mirror you require we look forward to reviewing your custom requirements and recommending the best solution.