Transparent Conductive Heaters Indium Tin Oxide (ITO)

Cockpit Displays ● Outdoor Imaging● Security & Surveillance● Incubators

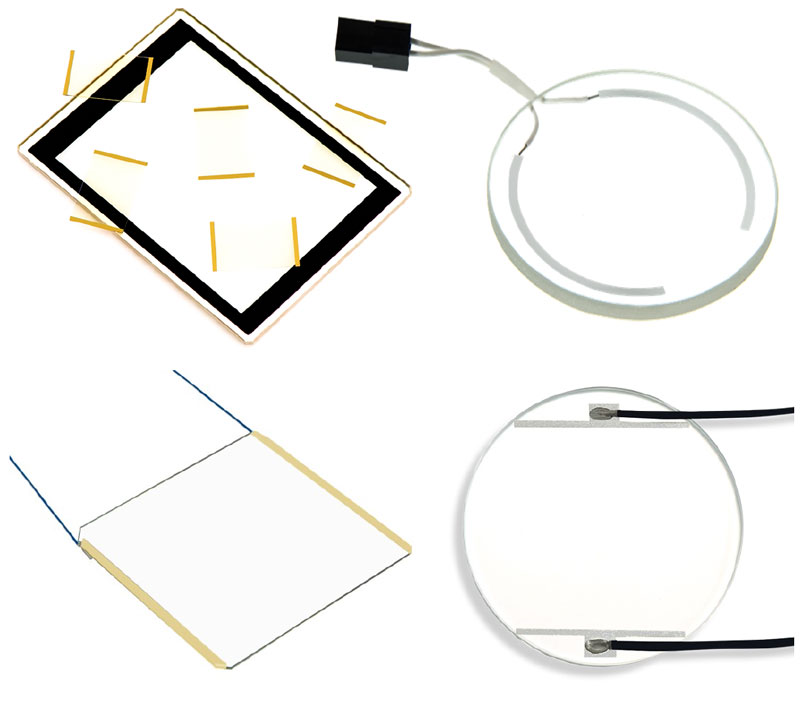

Abrisa Technologies’ Transparent Conductive Heaters incorporate coatings of Indium Tin Oxide (ITO), Index-Matched Indium Tin Oxide (IMITO) or Indium Molyb-denum Oxide (IMO) and are ideal window and display glass solutions when anti-fogging or de-icing, and high throughput and clarity are needed to maintain unobscured viewing and optical sensing in cold climates. The coatings deliver the high uniformity and low scatter performance needed to preserve high resolution digital imaging, sensing or display outputs while maintaining high throughput efficiency and clarity. Our solutions incorporate key heating attributes that can be tailored for specific needs, including design considerations for anti-reflective properties for visible, NIR, SWIR, and IR, optimization to air or index matched for bonding, and delivery of color neutral performance in transmission, reflection, or both.

Popular Substrate Materials

- SCHOTT BOROFLOAT® 33 – Low CTE, High T%

- SCHOTT D 263® T eco Ultra-Thin

- Low Iron Soda Lime – Economical Float Material

- Low & Non-Alkaline, Corning® Eagle XG®

- Corning® Gorilla®, AGC Dragontrail®, SCHOTT AS 87

- Customer Furnished Materials & Wafers

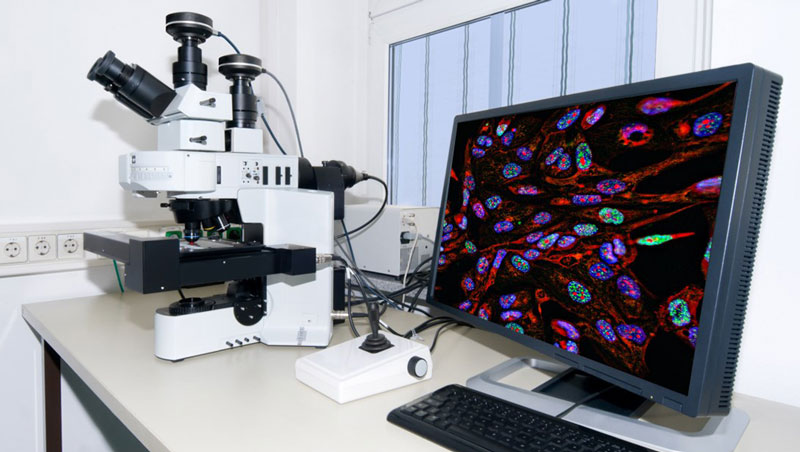

Our ITO, IMITO, and IMO heater solutions are perfect for outdoor security surveillance, traffic monitoring, aircraft flap monitoring, digital CMOS imaging applications, avionics cockpit displays, outdoor displays, robotic and 3D sensing machine vision in refrigerated environments, military vehicle turret viewing, and optically transparent incubator sample surfaces for live cell microscopy imaging.

These Ready-to-Install heater solutions incorporate your choice of technology glass, fabrication, HIE™ chemical strengthening or heat tempering, transparent conductive coatings, AR coatings, bus bars, electrical connectivity, wire bonding or soldering, connectors, screen printed ceramic frit or epoxy ink graphics, laser marking and applied gaskets.

Coatings & Solutions

- Indium Tin Oxide (ITO)

- Index-Matched Indium Tin Oxide (IMITO)

- Indium Molybdenum Oxide (IMO) for Infrared (IR)

- Cut-to-Order Fluorine Doped Indium Tin Oxide (FTO)

- Single, Buried & Accessible (ITO) Layer

- Coated Sizes from 5.0mm to 27” Diameter

- Bus Bars – Silver Epoxy, Silver Frit, CrNiAu

- Wire Bonding, Wire Solder & More

- Mounting Gaskets & Oleo/Hydrophobics

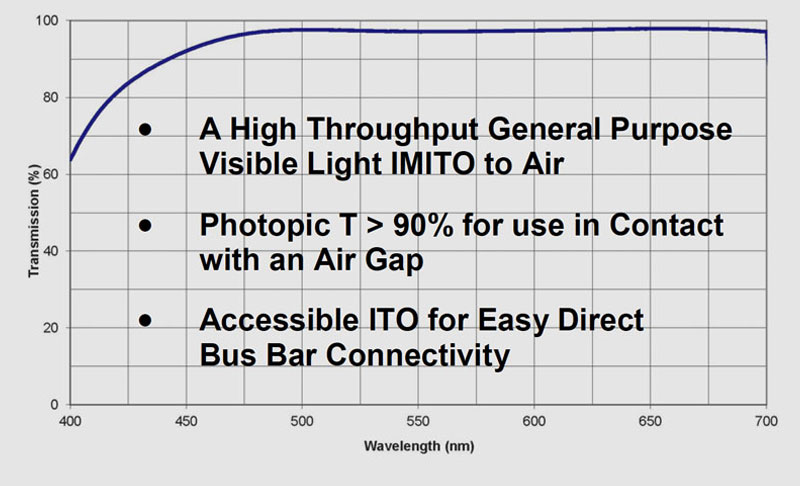

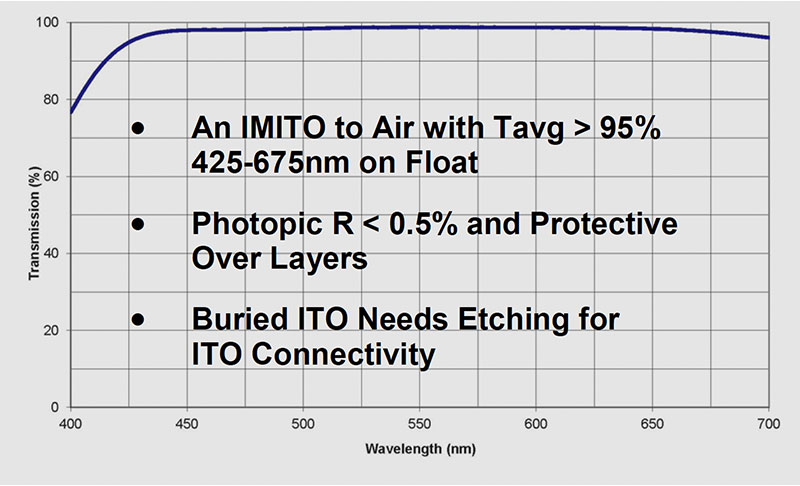

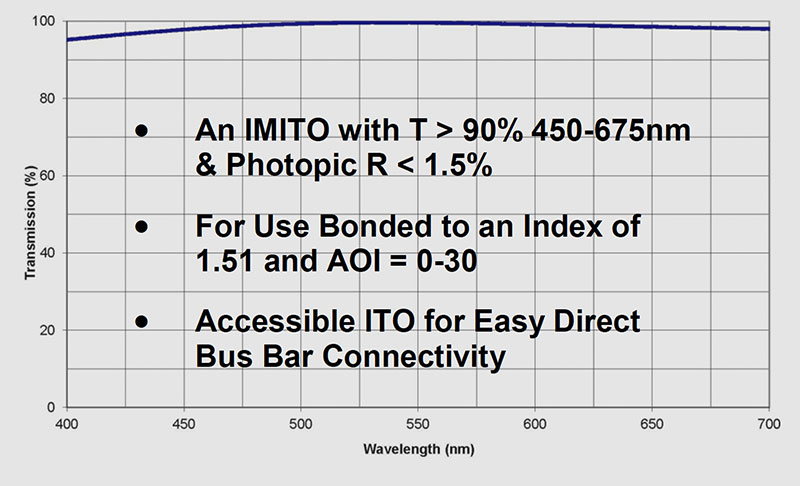

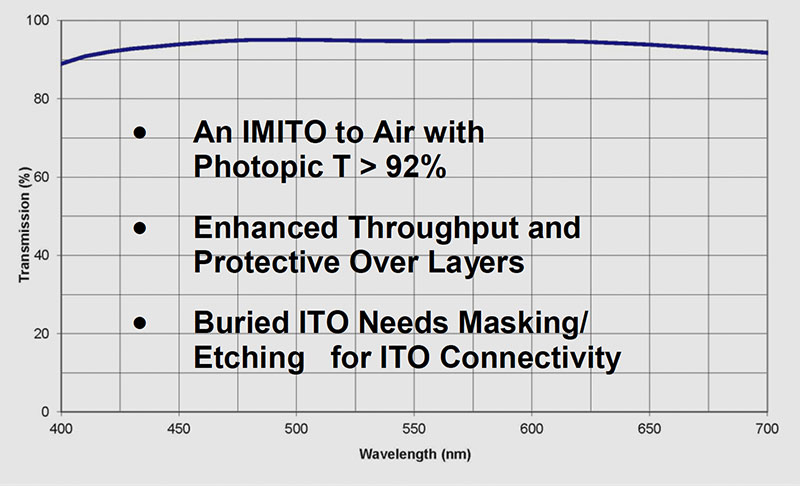

Heated windows incorporating transparent conductive coatings as Indium Tin Oxide (ITO) and Index-Matched ITO (IMITO) are ideal for digital imaging and display applications to help prevent fogging and ice build-up which can obscure both viewing and image capture. Abrisa Technologies specializes in the design of ITO/IMITO heater solutions optimized for enhanced throughput performance in air or other mediums and additional performance attributes addressing broad or custom viewing angles, spectral ranges, and challenging use environments.

Two Types of ITO/IMITO Constructs:

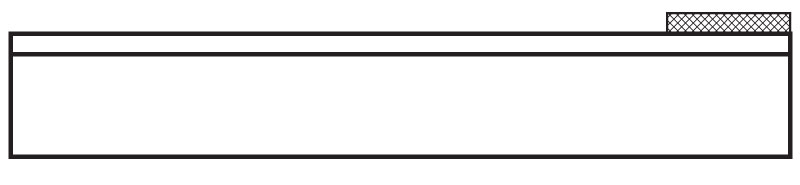

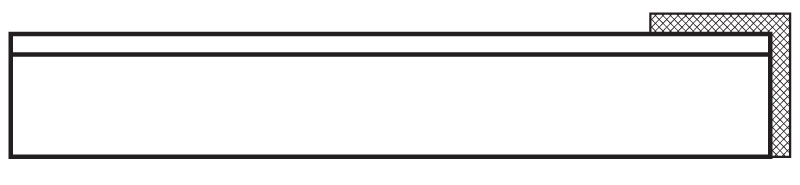

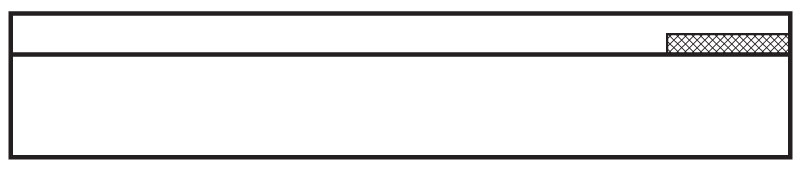

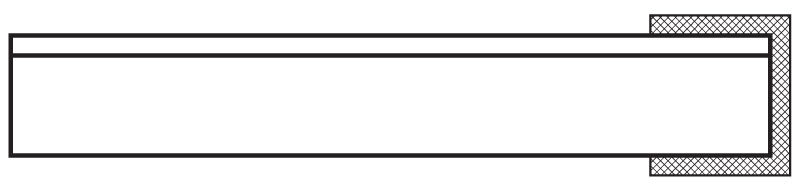

Accessible ITO/IMITO – The ITO is the top layer of the coating stack and readily available for connectivity contact via conductive gaskets or bus bar application.

Buried ITO/IMITO – The ITO layer is buried under or between dielectric layers. Used for higher abrasion or environmental durability, or design flexibility to achieve enhanced transmission and anti-reflection properties. Requires masking or etching to access the ITO layer for connectivity.

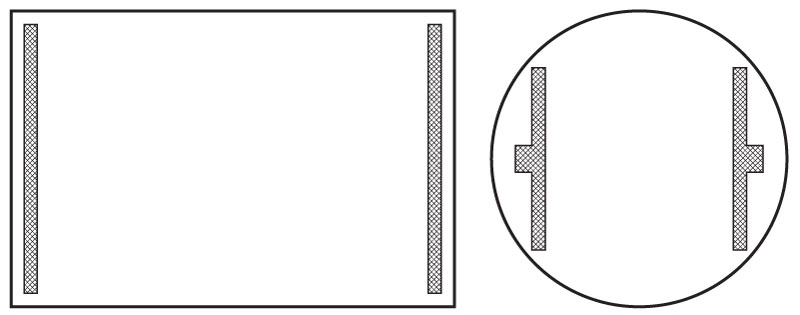

Bus Bars – Application Locations