Santa Paula, CA – Abrisa Industrial Glass, (AIG) a business unit of Abrisa Technologies provides coated heat resistant SCHOTT BOROFLOAT® (UV) Blocking Filter Glass. This non-heat absorbing glass has excellent optical characteristics including heat stability for consistent color balance and performance as well as rugged durability. The glasses characteristics make it ideal for use as a “safe viewing” UV Blocking optical window for UV curing systems, optical imaging systems, instrumentation, and as a UV filter in front of a lighting system, protecting viewers eyes from damaging UV radiation emittance.

Santa Paula, CA – Abrisa Industrial Glass, (AIG) a business unit of Abrisa Technologies provides coated heat resistant SCHOTT BOROFLOAT® (UV) Blocking Filter Glass. This non-heat absorbing glass has excellent optical characteristics including heat stability for consistent color balance and performance as well as rugged durability. The glasses characteristics make it ideal for use as a “safe viewing” UV Blocking optical window for UV curing systems, optical imaging systems, instrumentation, and as a UV filter in front of a lighting system, protecting viewers eyes from damaging UV radiation emittance.

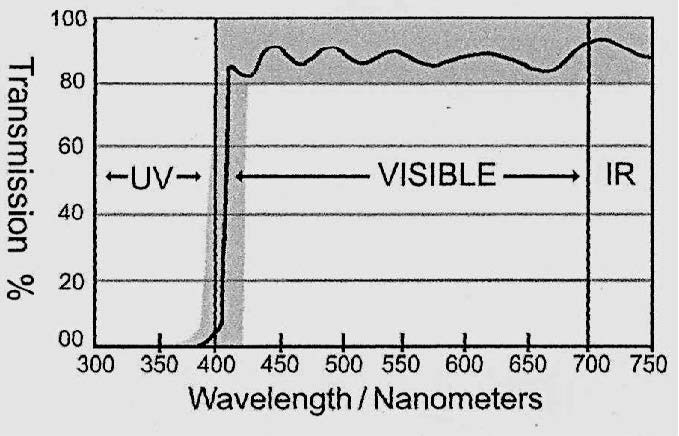

Protecting eyes from strong UV light reduces the risk of cataracts, retinal damage, and the possibility of eye cancer. By utilizing Abrisa Technologies UV blocking glass, 99% of the harmful UV radiation below 400nm is mitigated, while transmitting high-quality light exceeding 85% with virtually no color or viewing distortion due to the sharp filter cutoff, rendering an index of 95 in the visible light region. Photopic vision efficiency “human eye response” also exceeds 85%.

According to Susan Hirst, General Manager for AIG, “Advantages of our SCHOTT BOROFLOAT® UV Blocking Glass include the reduction of photochemical degradation, enabling the use of a broader range of light sources, allowing increased light levels without risk of eye damage, and preventing filter damaging heat build-up.” She further states, “One of the significant benefits of using our UV blocking glass/filter is that it has a much longer life than plastics or gels which can degrade over time. The thin film dielectric coating is deposited on 1-side of color neutral SCHOTT BOROFLOAT® glass and is extremely durable with abrasion and crack resistance.”

Available in sheet sizes of 10” x 30” (254 mm x 762 mm) and a thickness of 3.3mm, our UV Blocking Glass can have a host of value-added services applied for a Total Solution approach meeting a wide variety of application specific requirements. These services include AR coating and custom fabrication such as cutting, machining, edging, laser marking, screen printing, CNC processing, drilling, grinding and more.