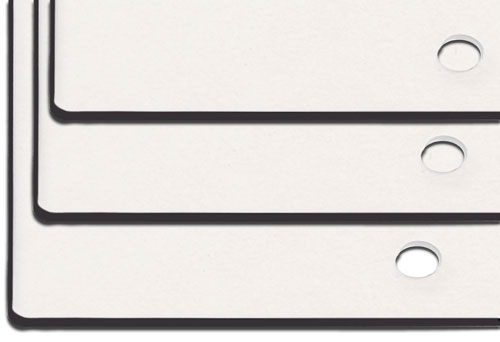

Unframed and flush mounted display cover and enhancement filter glass can sometimes allow undesired “backlight” bleeding or light leakage/scatter to emanate from the display edges and corners. This can occur when the border of the display glass is not fully integrated, covered or masked in some way. “Backlight” bleeding is problematic as it can be distracting to the viewer, particularly when viewing dark screens in low lighting conditions.

Unframed and flush mounted display cover and enhancement filter glass can sometimes allow undesired “backlight” bleeding or light leakage/scatter to emanate from the display edges and corners. This can occur when the border of the display glass is not fully integrated, covered or masked in some way. “Backlight” bleeding is problematic as it can be distracting to the viewer, particularly when viewing dark screens in low lighting conditions.

According to Susan Hirst, General Manager for Abrisa Industrial Glass (AIG) a division of Abrisa Technologies a HEF Photonics Company, “AIG provides edge printed solutions for display cover and enhancement glass that minimizes “backlight” bleeding where we add opaque borders of epoxy or frit ink to block the pathways when it is undesirable for light to exit.” She further adds, “The application of the black or other opaque PMS color matched ink is compatible with bonding requirements and specifications and can be applied to glass substrates as small as ¼” square or up to an 80” diagonal. The ink can be applied to glass as thin as 0.7 mm up to 1” in thickness with ink profiles down to 0.0003” and tolerances of ±0.010.”

When choosing the best edge and face printing process and ink, several parameters should be considered: aesthetics, optical functionality, and use environment. Epoxy inks provide a good balance of economical cost and good performance. Epoxy inks deliver good opacity, adhesion, low profiles and moderate robustness for abrasion and adhesion. These inks come in a large range of PMS colors and are well suited for use application on thinner substrates. Frit ink is composed of glass and ceramic particles and delivers exceptional durability, abrasion, temperature resistance, and superior adhesion and is best suited for thicker substrate materials as SCHOTT Borofloat® 33, fused silica, or heat tempered soda lime float glass which can withstand the high curing temperatures.

Susan also states “In addition to edge printing, Abrisa Technologies has extensive flat glass screen printing capabilities using both semi-automatic and automated printers within a Class 1000 or 10000 cleanroom. The platform selected for the screen print is dependent upon the glass substrate end-use specification requirements. Inks are available in multiple colors including metallics and range from low temperature epoxies to high temperature frits. Abrisa Technologies generally stocks black and silver epoxies and black frit. Other inks are available for custom requirements including multiple colors and metallics.”