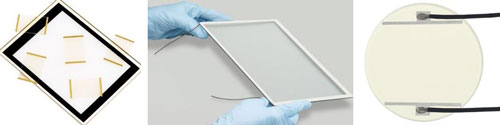

Abrisa Technologies transparent conductive coatings such as Indium Tin Oxide (ITO), Indium Molybdenum (IMO) or Index-Matched (IMITO) are used to make robust transparent electro-magnetic shielded (EMI) display enhancement glass, anti-fogging/frost-free camera windows, and controlled temperature sample surface for live cell imaging. Bus bars provide the pathways for electrical connectivity or grounding points to the coating and are themselves, made of conductive material.

Abrisa Technologies transparent conductive coatings such as Indium Tin Oxide (ITO), Indium Molybdenum (IMO) or Index-Matched (IMITO) are used to make robust transparent electro-magnetic shielded (EMI) display enhancement glass, anti-fogging/frost-free camera windows, and controlled temperature sample surface for live cell imaging. Bus bars provide the pathways for electrical connectivity or grounding points to the coating and are themselves, made of conductive material.

According to Susan Hirst, General Manager for Abrisa Industrial Glass (AIG) a division of Abrisa Technologies, “Bus Bars are offered in strip, full perimeter, and other controlled patterns either on top of or under the transparent conductive coating with connection point options possible at the surface, side or rear surface.” Susan further adds, “We offer Total Solutions inclusive of transparent conductive coatings, bus bars, and wire bonding on our diverse supply of fabricated specialty glass.”

Various Bus Bar material types include highly conductive and solderable Chrome-Nickle-Gold, economical and easy-to-pattern silver epoxy in 3 bond surface options (Top, L & U Shape), and high adhesion, solderable, and durable, silver frit. Transparent conductive coatings available include, Single Layer Indium Tin Oxide (ITO), Index-Matched IMITO, Indium Molybdenum Oxide (IMO), and Fluorine Doped Tin Oxide (FTO).

The Bus Bars and Transparent Conductive Coatings can be applied to a variety of substrate materials depending upon the application specific requirements:

- SCHOTT Borofloat® 33 – Thermal Resistance, High Transparency

- SCHOTT D 263® T eco – Ultra-Thin, Broad Transparency Range

- Low Iron Soda Lime – Economical, HIE™ Strengthened Option

- Low & Non-Alkaline Glass (AGC EN-A1, Corning® Eagle XG®

- HIE™ Materials – Corning Gorilla Glass, AGC Dragontrail®, SCHOTT AS 87

- Customer Furnished Material for Coating & Bus Bars