Thin & Ultra-Thin Glass Fabrication & Coating

Abrisa Technologies offers ultra-thin (≤0.4mm) technology glass for next generation devices needing miniaturization, slim formats, flexible glass, lightweight components, or bio or chemical compatibility. Glass solutions have optical properties well suited for imaging, LiDAR, scanning, control panels, displays and windows. In addition to our broad selection of ultra-thin borosilicates, HIE™ aluminosilicates, low fluorescence and low alkaline glass options, we provide glass fabrication, HIE™ strengthening, optical coating, screen printing and packaging for ready-to-install Total Solutions.

Applications

Displays & Instrument Panels

- Ultra-Thin Protective Cover Glass

- Low Profile Displays/Human Interface

- Low Alkali Mobility for Active Matrix Displays

- Sunlight & Heat Resistant In-Cabin Displays

Imaging, Sensing, Scanning, Portables

- Damage Resistant LiDAR Scan Optics

- Lightweight Windows & Filters for Portables

- Ultra-Thin ITO EMI Shields & Heaters

- Wafer-Based Micro-Optics for AR, VR Telecom

- “Non-Ghosting” Optics & Beam Splitters

- Optical Filters for Sensors & Diodes

- Biotech Sample & Prep Slide Surfaces

Thin Glass ≤ 0.7mm

Damage Resistant Glass

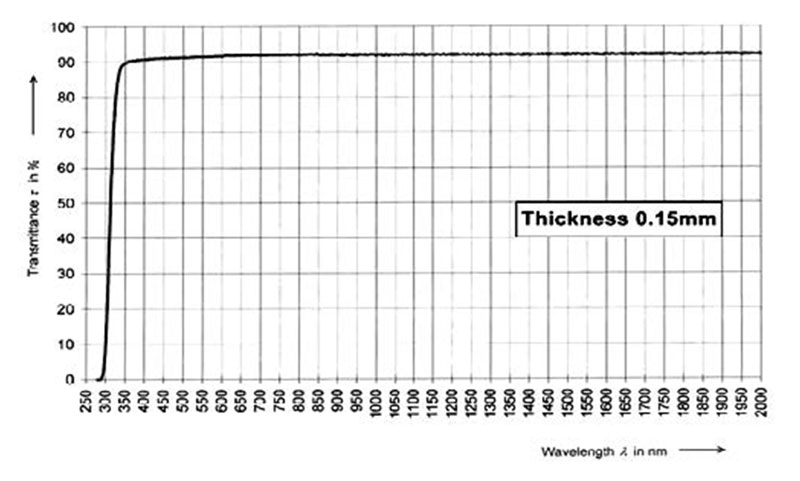

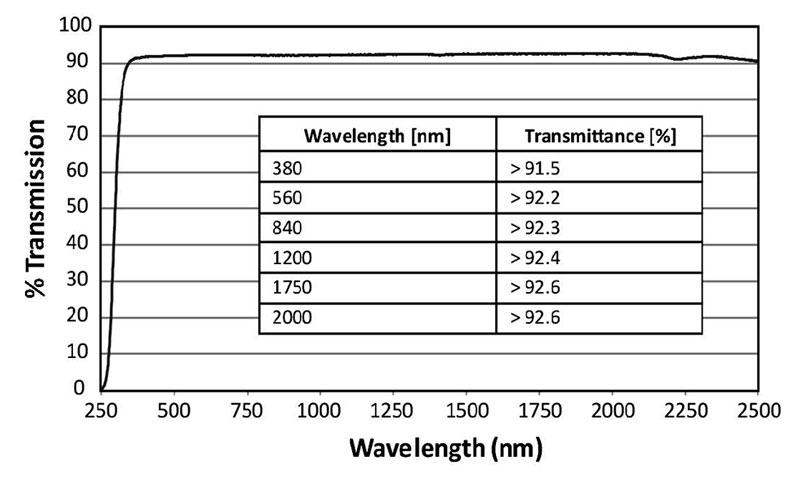

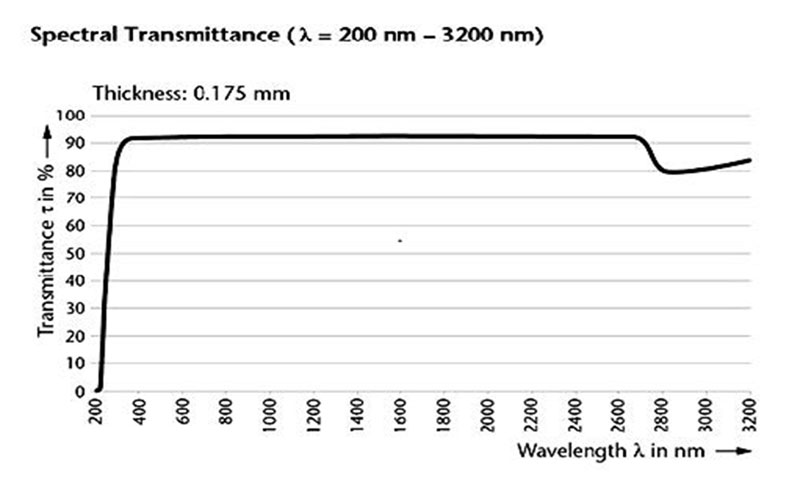

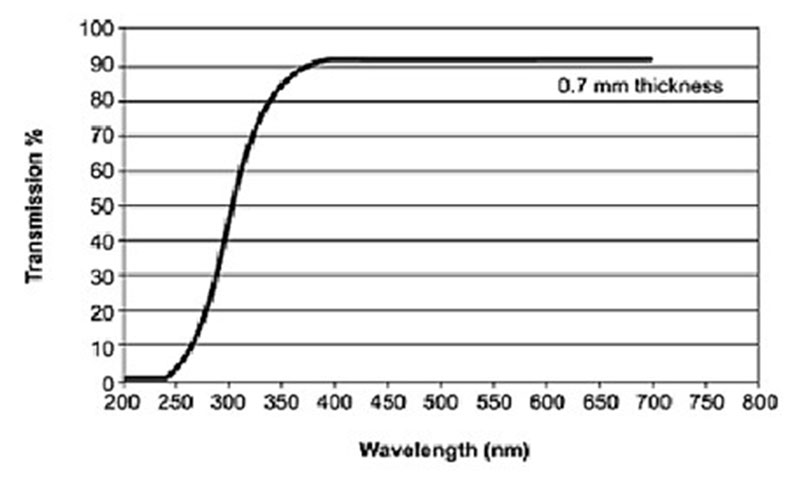

- SCHOTT Borofloat® 33 (0.7mm)

Low Fluorescence/Low Alkaline Glass

- AGC EN-A1 (0.3mm)

- Corning® Eagle XG® (0.55 & 0.7mm)

Ultra-Thin Glass ≤ 0.4mm

Damage Resistant Glass

- SCHOTT AS 87 eco Aluminosilicate (0.1 – 0.33mm)

- Corning® Gorilla® Glass 3 (0.4mm)

Low Fluorescence Glass

- SCHOTT D 263® T eco Borosilicate (0.07 – 0.4mm)

- Soda-Lime Float (0.2mm)

HIE™ Aluminosilicate Fusion-Draw & High Ion-Exchange (HIE)

(0-300°C)

HIE™ Aluminosilicate

(20°C - 300°C)

Alkaline Earth Borosilicate

(0-300°C) Low & Close to Si

Advanced Borosilicate Downdrawn

(20°C - 300°C) Similar to Metals for Sealing

Alkali-Free Boro-Aluminosilicate

(50°C - 250°C) Close to Si

Advanced Borosilicate Float Glass

(0°C - 300°C) Low & Close to Si Resistant to Thermal Gradient & Shock

(0°C - 300°C)