SCHOTT D 263® T eco Ultra-Thin Glass

SCHOTT D 263® T eco is a clear, lightweight, low fluorescence, borosilicate glass available from Abrisa Technologies in thicknesses from 0.03 mm to 1.1 mm with excellent transmission and high chemical resistance. The glass is made with the SCHOTT specific down-draw method that results in excellent surface finish and low surface roughness typically < 1 nm rms range. Abrisa Technologies specializes in ultra-thin glass fabrication and optical coating as well as, screen printing, laser marking, oleo/hydrophobic coating, and other value added services.

Actual part size is 3mm x 3mm

D 263® T eco makes an excellent choice for ultra lightweight mobility and scanning applications, ultra-low profile displays and devices, micro-electronics, sensors, chemical process resistant slides, and sample platforms.

D 263® Applications

- Lightweight Windows and Mirrors for Mobility

- Wafer-Based Micro-Optics for AR,VR, Telecom

- Optical Caps for Sensors and Diodes

- Ultra-Thin ITO Heaters and Bus Bars

- Biotech Sample and Slide Surfaces

- Sunlight and Heat Resistant In-Cabin Displays

- Low Profile Displays/Human Interface

- Low Alkali Mobility for Active Matrix Displays

- Ultra-Thin Cover Glass

- Additive Optical/Mechanical Attributes

Actual glass thickness as show is 0.07mm

D 263® Sheet Sizes

510 mm x 430 mm > 0.2 mm (Thickness) & 440 mm x 360 mm ≤ 0.2 mm (Thickness)

* According to SEMI MF 1530 GBIR

** Special request only

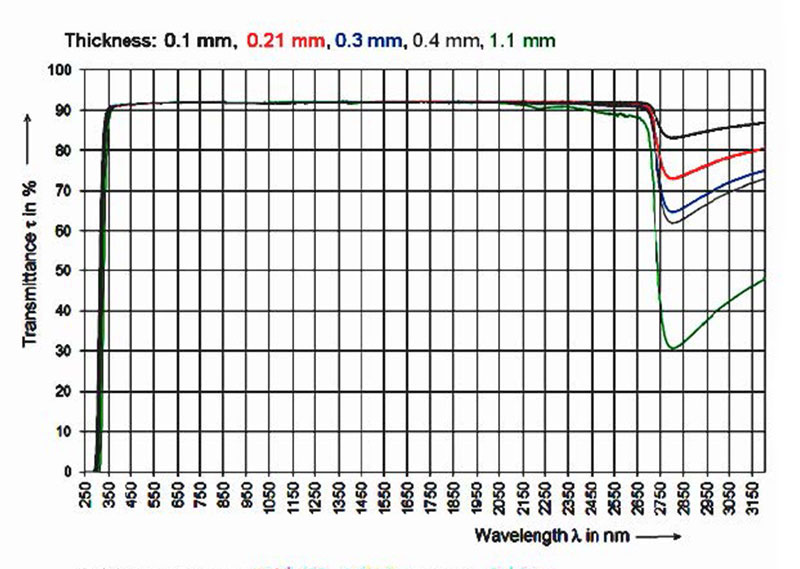

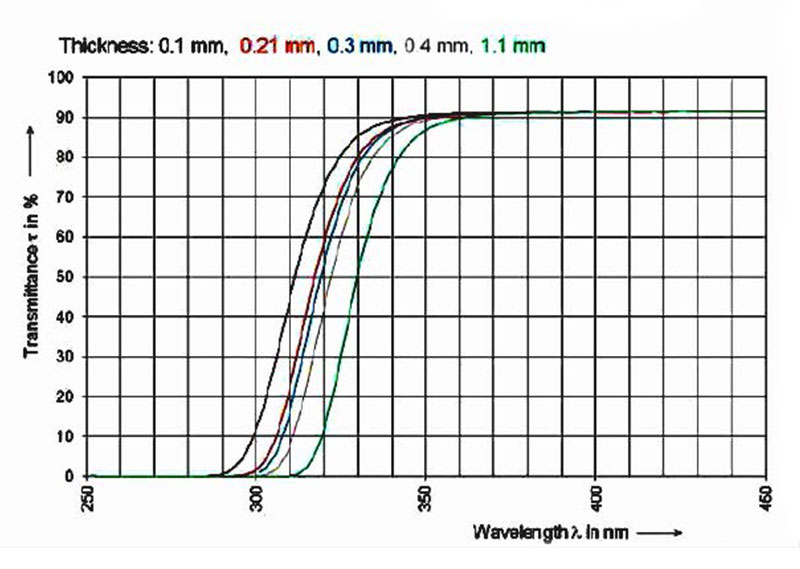

D 263® Optical Properties

D 263® Electrical Properties

D 263® Thermal Properties

α (20 °C; 300 °C) in 10-6 K-1 (Static Measurement)

α (20 °C; 300 °C) in 10-6 K-1 (Static Measurement)