SCHOTT BOROFLOAT® 33 Borosilicate Float Glass

SCHOTT BOROFLOAT® 33 is a UV-NIR transparent borosilicate float glass with excellent optical properties and smooth low scatter surfaces straight off the float process. SCHOTT BOROFLOAT® is an economical high performance material, making it ideal for the volume manufacture of windows, mirrors, filters, display glass, 3D build platforms, and other components. SCHOTT BOROFLOAT® 33’s composition lends itself to outstanding thermal resistance and sharp impact crack resistance, making it an excellent choice for challenging use environments. In addition to SCHOTT BOROFLOAT®, Abrisa Technologies offers a wide selection of other technical glass substrate materials, custom fabrication, heat toughening, optical coating, electrical connectivity, screen printing, applied films, oleophobics, laser marking, and more for a Total Solution.

BOROFLOAT® Features

- Optical Quality BOROFLOAT® Borosilicate Glass

- High Transparency/Color Neutral

- Broad Spectral Range UV-VIS-NIR

- High Thermal Resistance (Shock & Gradient)

- Crack Resistant to Sharp Impact

- Low Thermal Expansion for Tight Seals

BOROFLOAT® Applications

- Outdoor VIS-NIR Image Sensing

- “True Color” Medical Imaging

- High Intensity Lighting & Curing Filters

- Heated 3D Additive Build Platforms

- Industrial Sight Glass View Ports

- Specialty Ruggedized Displays

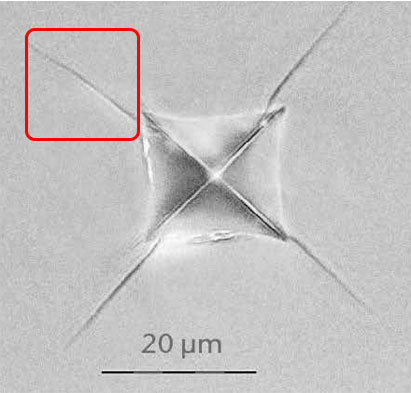

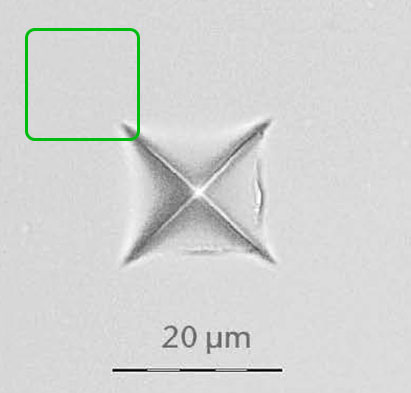

Soda-Lime vs. SCHOTT BOROFLOAT® 33 Sharp Impact Crack Resistance

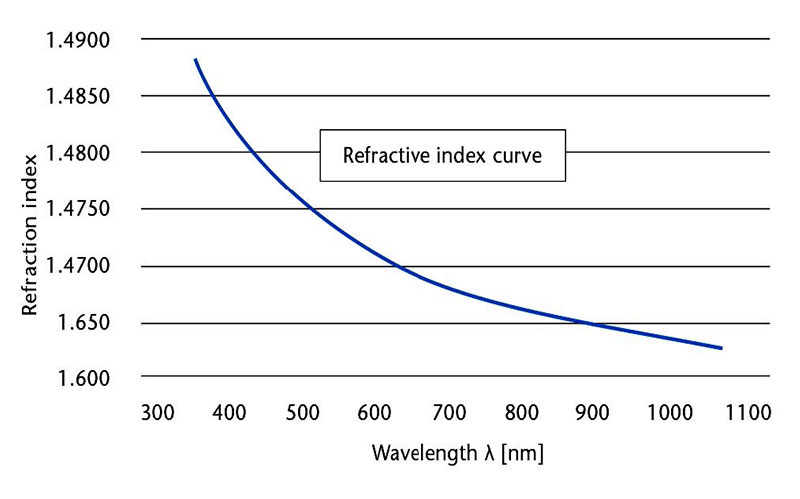

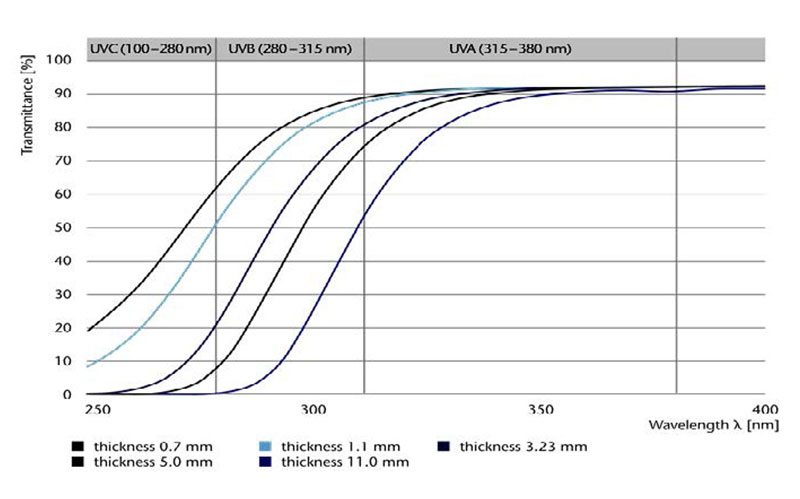

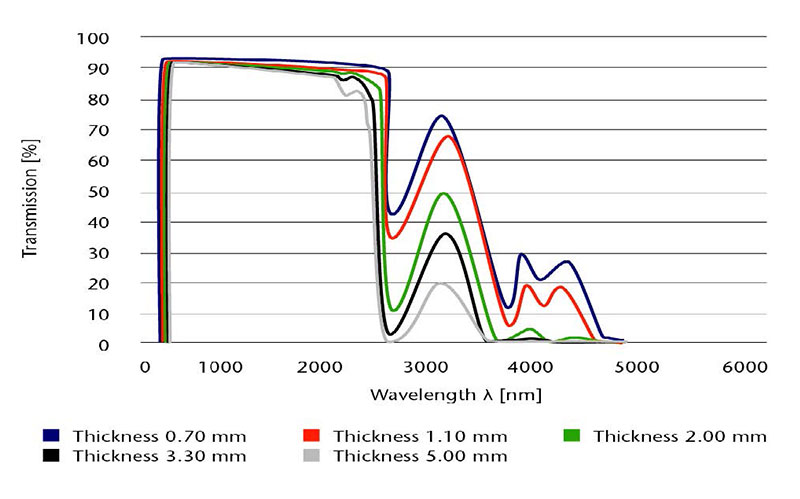

BOROFLOAT® Optical Properties

- Broad spectral range UV-VIS-NIR

- High Transparency/Color Neutral

- Excellent for Imaging/Sensing, Specialty Lighting

BOROFLOAT® Mechanical Properties

- Sharp Impact Crack Resistant

- Scratch Resistant

- Abrasion Resistant

BOROFLOAT® Thermal Properties

- Thermal Shock Resistant

- Thermal Gradient Resistant

- High Melting Point

Resistance to Thermal Gradients (RTG) & Resistance to Thermal Shock (RTS) must be considered when determining max. operating temperatures.

*According to ISO 7991

*Consult factory for availability

*Consult factory for availability