AGC Dragontrail™ Chemically Strengthened Glass

Asahi Glass Corporation (AGC) Dragontrail™ is innovative High Ion-Exchange (HIE™) aluminosilicate glass with superior strength, scratch resistance and a beautiful surface finish that is made by applying a proprietary chemical strengthening and tempering process to the highly even and flat float material.

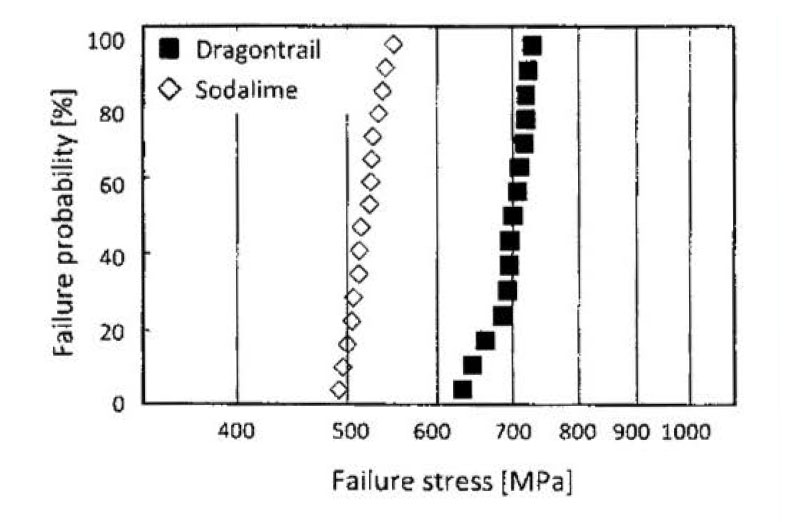

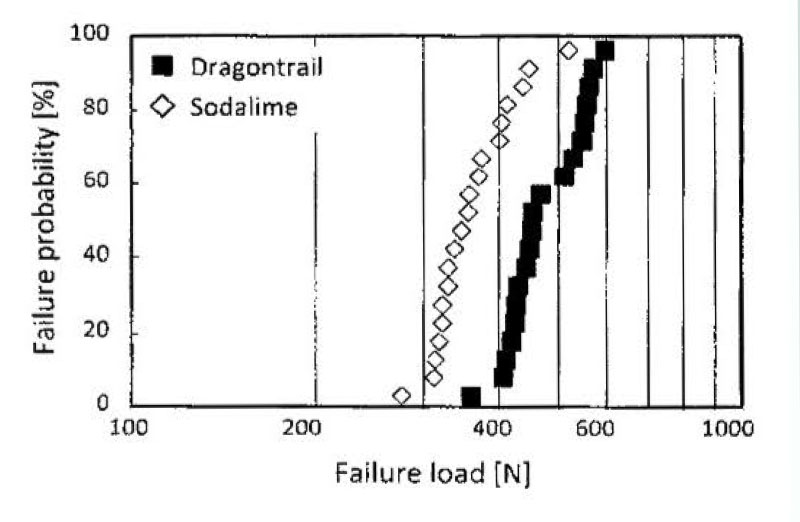

Dragontrail™ supports low profile and reduced weight portable field and industrial devices with a toughness 6x that of soda lime float. It is environmentally friendly and is produced without the use of lead, arsenic and antimony.

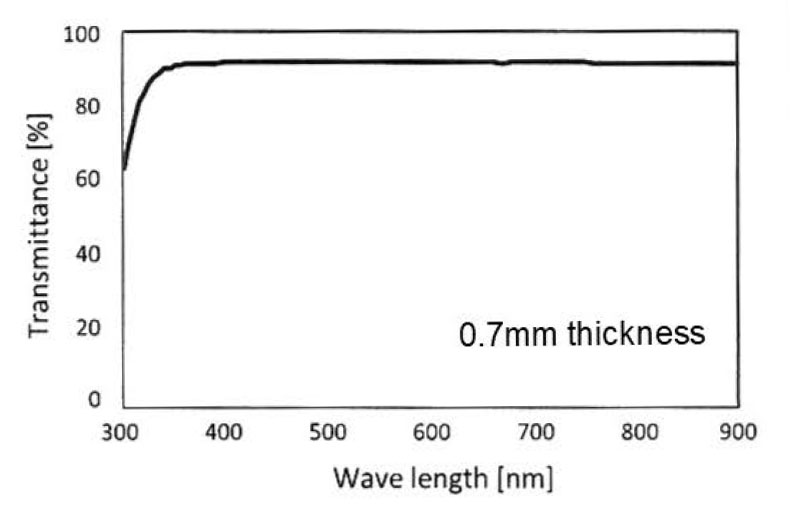

Dragontrail™ is an excellent choice of a transparent and damage resistant window or display enhancement glass that helps to enhance the usable lifetime of high contact touch displays, field and industrial image sensors, document scanners and on board vehicular and avionics displays.

Features

- 6x stronger than soda lime float glass

- Damage and scratch resistant

- Vicker’s hardness 673

- > 600 MPa strength

- < Depth of Layer* (DOL) < 45µm

* Depth of Layer (DOL) is a measurement of the compressive strength of the glass specific to chemically strengthened glass. It is the depth into the surface of the glass to which compressive stress is introduced. It is defined as the distance from the physical surface to the zero stress point internal to the glass.

Applications

- Display cover glass

- Sensor windows

- Mobile touch device displays

- Scanner beds

- Industrial machine vision

- Obstacle avoidance

Sheet Sizes

- 48″ x 29″ (1219.2mm x 736.6mm) standard

- 60″ x 48″ (1524mm x 736.6mm) available**

Thicknesses

- Stock thicknesses include 0.8mm and 1.1 mm

- Ranging from 0.5mm to over 5mm may be available upon special request**

** Minimum order quantity may apply, confirm prior to order placement.