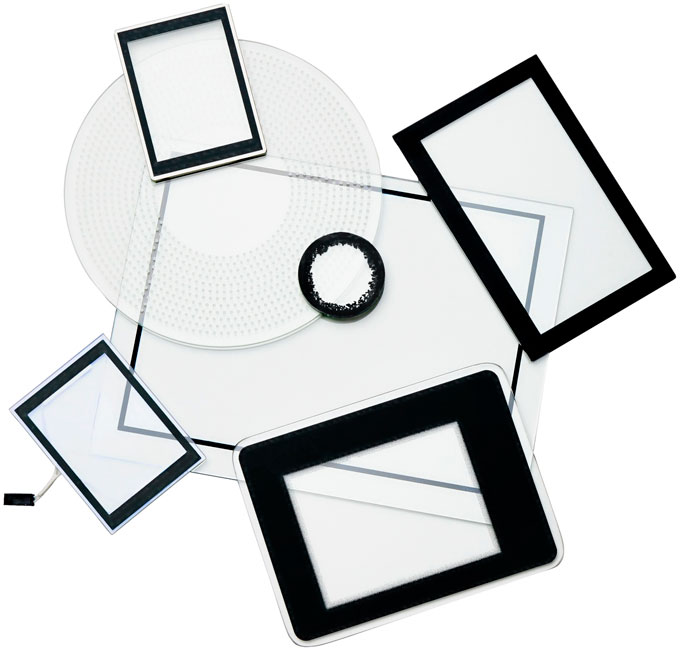

Glass Screen Printing

Screen Printing at Abrisa Technologies’ Santa Paula facility is performed on either a semi-automatic printer or automated printer within a Class 1000 or 10,000 cleanroom. The platform selected is dependent upon need and spec requirements. Inks are available in multiple colors including metallics and range from low temperature epoxies to high temperature frits. Abrisa Technologies generally stocks black and silver epoxies and black frit. Other screen printed glass inks are available for custom requirements including multiple colors and metallics.

You may also be interested in Screen Printing vs. Digital Printing on Glass.

Ekra X4

Argon – Large Format

Cameo/Saturn

Saturn

Custom Press

Screen Printed Glass Ink Types

Epoxy/Polyester

Thickness Requirements

Frit

Etching & Bus Bars

Abrisa provides etching and busbar applications per project specifications such as silver epoxy or conductive ink printed on an ITO or IMITO. The etching and busbar process is available on the Ekra X4, Cameo 18, Cameo 30, and Saturn. L-shaped and U-shaped bus bars are also available through edge printing. The size and tolerance limitations are the same as standard screen printing.

Learn more about Bus Bars for Transparent Conductive Coatings

Edge Printing

Edge printing for small to medium sized parts is available for any application with ceramic frit ink. Generally there are no limitations on part size or material thickness. However, for epoxy ink the largest part with edge printing is typically 72″ x 54″. Tolerances are up to ±0.010″.

Learn more about Minimizing Light Leakage & Light Scatter by Edge Printing Display Cover and Enhancement Filter Glass