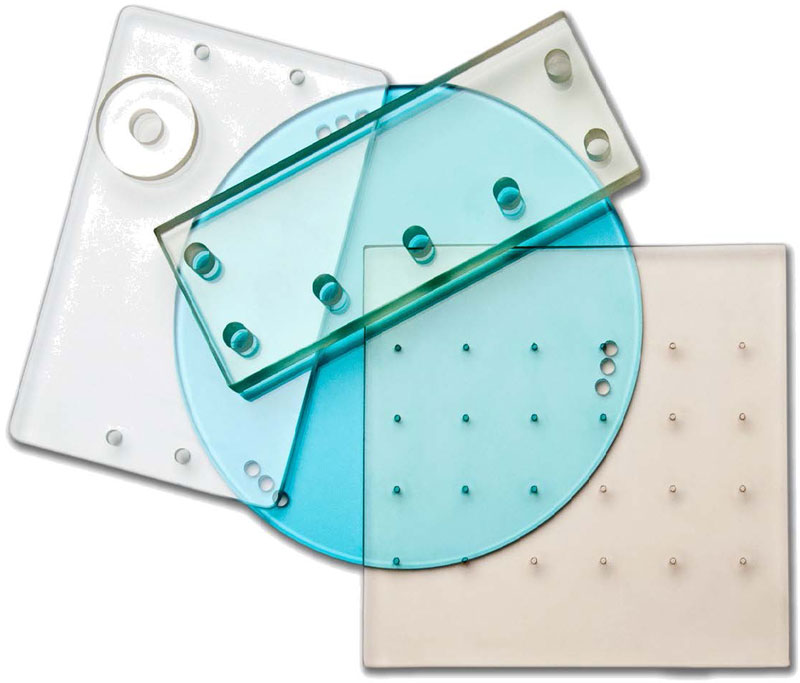

Glass Machining

Abrisa Technologies provides multiple technologies/processes to support your glass/optics shapes, surfaces, edging, and hole drilling requirements. Depending on glass types, thicknesses, hole diameter, and edge quality; Abrisa Technologies can choose between CNC machining, opposed edge drilling, or abrasive material removal or sandblasting to meet your specific glass fabrication requirements.

You may also be interested in Can Strengthened Glass be Machined?

CNC Processing

Shapes, Notching, Slotting, Grooving & Step Surface

CNC machining can provide any custom shape with any type of ground or polished edging, including parts with holes, tapers, notches, slots, grooves, or stepped surfaces.

Drilling

Holes & Tapers

Abrisa Technologies provides multiple avenues to drill holes. Hole parameters are only limited by the CNC machining capabilities stated on this page.

- Through Holes

- Blind Holes

- Step Holes

- Countersink Holes

Countersink & Inside Dimension Seaming

Parts with holes, slots, or grooves can be tapered on both sides or seamed on the inside dimensions to improve inside edge quality. The only limitations are from the CNC machining capabilities stated above.

Grinding & Polishing

Buffing & Lapping

Parts with special surface or edge polishing requirements can be ground to size, rough surface ground (lapping), or smooth polished (buffing).

Surface Grinding & Polishing

*Thickness tolerance of ±0.025 mm [±0.001″] applies to parts 127 x 127 mm [5″ x 5″] or smaller.

Edge Grinding and Polishing

*Thickness tolerance of ±0.05 mm [±0.002″] applies to parts 127 x 127 mm [5″ x 5″] or smaller.

Sand Blasting

Surface Patterns & Logos

Portions of the part or the entire part can be sandblasted for a rough or cloudy surface finish or logos and patterns can be applied to the surface of the part. The inside or outside surfaces of tubing can also be sand blasted for a rough or cloudy surface finish. Sandblast grits available from 80-400.

Circle Grinding

High volumes of circular parts can be quickly ground to precise diameters.

Learn more about our Glass Machining Capabilities.