Non-Glare or Anti-Glare glass breaks up incident light reflected images, allowing the user to focus on the display image versus the reflected images. Unlike anti-reflection coated or untreated surfaces, anti-glare etched glass does not become highly reflective as a result of oily finger prints.

Non-Glare or Anti-Glare glass breaks up incident light reflected images, allowing the user to focus on the display image versus the reflected images. Unlike anti-reflection coated or untreated surfaces, anti-glare etched glass does not become highly reflective as a result of oily finger prints.

Abrisa Technologies anti-glare glass is manufactured by a controlled acid etch process yielding uniform diffused surfaces for anti-glare, high resolution.

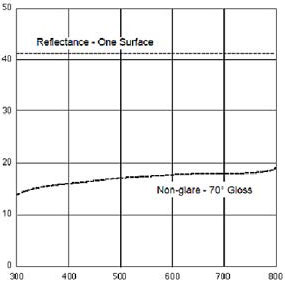

Varying levels of diffusion specified as gloss yield different levels of reduced glare. A lower gloss reading denotes a more diffuse panel. The more diffuse the panel surface, the more glare reduction it provides. However, an inverse relationship exists between the degree of diffusion and the panel’s resolution.

Specular Gloss & Gloss Units

Specular gloss is quantified by measuring the amount of light reflected from the sample and comparing it with the amount of light reflected when a polished black glass calibration standard is measured under the same conditions. The glass standard is assigned a value of 100 gloss units. Any surface that reflects more light than the black glass standard will produce a glossmeter reading of greater than 100 gloss units.

Specular gloss is quantified by measuring the amount of light reflected from the sample and comparing it with the amount of light reflected when a polished black glass calibration standard is measured under the same conditions. The glass standard is assigned a value of 100 gloss units. Any surface that reflects more light than the black glass standard will produce a glossmeter reading of greater than 100 gloss units.

The glossmeter illuminates a test surface at a defined angle of incidence and measures the amount of light at a defined angle of reflection. Since basic physics tells us that the angle of incidence is equal to the angle of reflection, it is convenient to refer to one angle only and this is generally referred to as the “geometry” of the instrument.

The lower the gloss units, the less glare. Abrisa Technologies can provide non-glare or anti-glare soda lime glass with the following gloss unit specifications:

- 60º – This is the highest level of etching, least amount of glare and reflectivity

- 65º

- 75º

- 90º

- 100º

- 110º

- 120º

- 130º

- 140º – This is the lowest level of gloss, most similar to untreated glass