The ZC&R Coatings for Optics division of Abrisa Technologies, designs and manufactures autoclavable coatings such as custom anti-reflection, mirror and filter coatings for use in medical and dental environments where demanding optical performance and harsh sterilization processes are often employed to prevent contamination of instrumentation.

The ZC&R Coatings for Optics division of Abrisa Technologies, designs and manufactures autoclavable coatings such as custom anti-reflection, mirror and filter coatings for use in medical and dental environments where demanding optical performance and harsh sterilization processes are often employed to prevent contamination of instrumentation.

Many imaging and endoscopic surgical instruments and devices come in direct contact with the human body during use or reside in a hospital or laboratory environment where biological or cross contamination is a risk factor. Some instruments are manufactured with disposable parts, but where not possible for cost or other reasons, must employ cleaning processes to achieve sterilization. In many cases, such processes involve autoclaving, high heat, high moisture and agitation, exposure to UV light, and sometimes surfactants or other harsh chemicals in an effort to remove and kill off bacteria and other contaminants. Most commercially available optical coatings are not designed to withstand the abuses of such rigorous cleaning methods and will often craze, delaminate or experience deterioration in their optical performance over a short period of time.

Optical elements in these types of medical and dental devices not only have to perform optically to enhance throughput efficiency, separate or combine portions of the light source spectrum, they must also survive the device assembly and cleaning processes. It is not uncommon for externally facing optical elements to be brazed into an assembly so as to provide permanent mounting and good hermetic and environmental seals. The brazing process in and of itself, involves high temperatures and often localized rapid temperature ramps.

ZC&R Coatings for Optics collaborates with customers to give careful consideration to the selection of optical substrates, mounting configurations and coating materials in order to minimize risk for crazing and damage by thermal and chemical cleaning and assembly processes used in medical and dental markets.

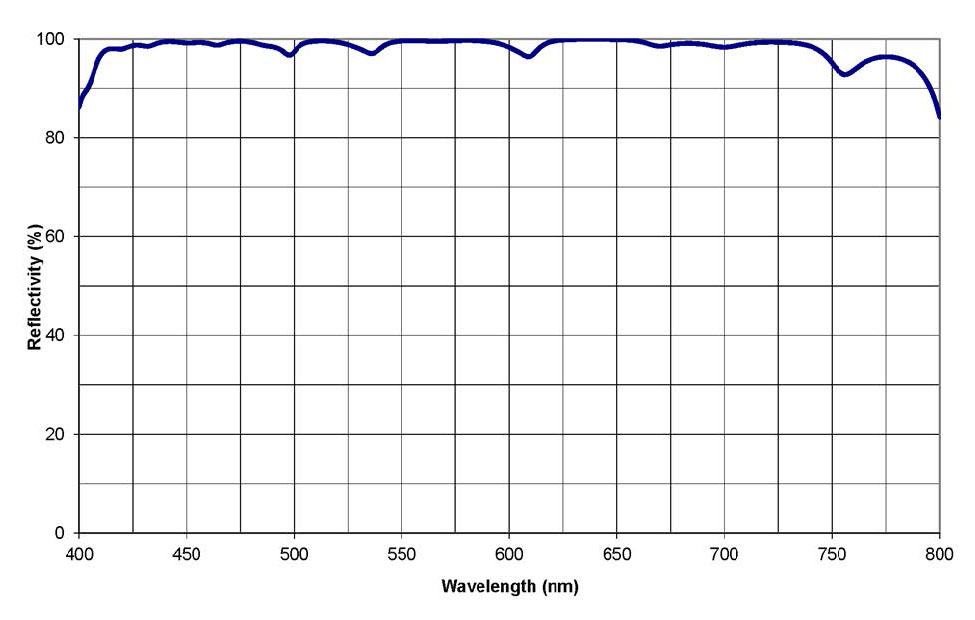

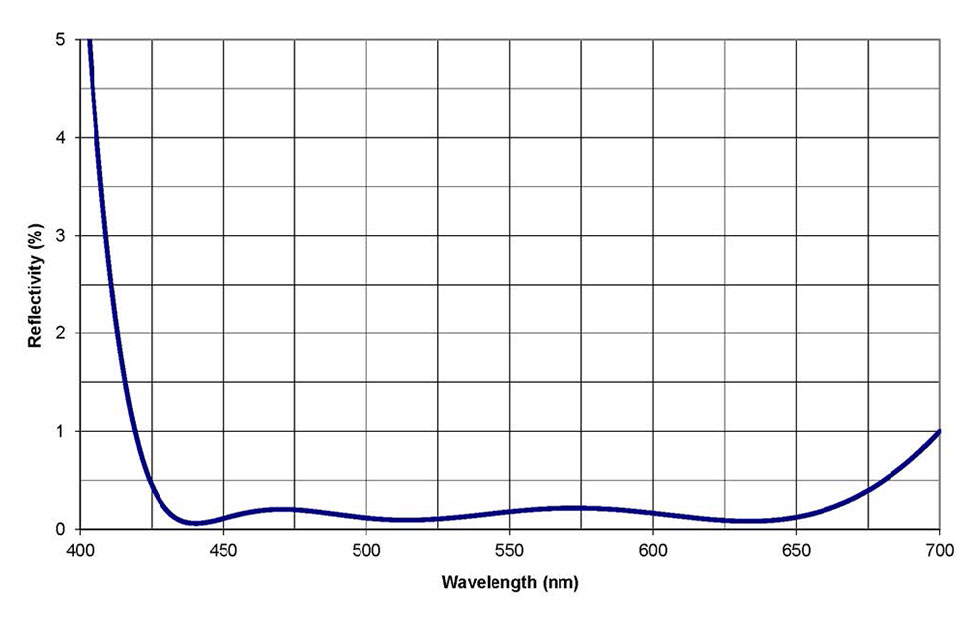

Employing coating design and deposition processes that lend themselves to supporting low stress under these conditions while simultaneously achieving demanding optical results is critical. The coating must be sufficiently dense in order to not be permanently affected by high moisture present in the cleaning processes. Often, the optical elements may be required to deliver sharp cut-off or cut-on performance, or ultra-high reflectance or filter characteristics which dictate fairly thick multi-layer coatings be employed, further increasing any risk factors for potential crazing.

Abrisa Technologies has years of experience providing optics for the medical and dental markets. Our economical and high performance custom durable coating solutions are engineered to survive tough cleaning and assembly environments, by design.