Sight glass, also known as a sight window or view port window, is a visual observation window made from a robust glass substrates such as SCHOTT Borofloat® and is used to verify conditions in piping, vessels, chemical reactors or other industrial equipment. Sight glass is generally subjected to elevated temperatures, chemical attack and high pressure. So selecting the appropriate glass substrate is critical in order to ensure safety even in the harshest of environmental conditions.

Sight glass, also known as a sight window or view port window, is a visual observation window made from a robust glass substrates such as SCHOTT Borofloat® and is used to verify conditions in piping, vessels, chemical reactors or other industrial equipment. Sight glass is generally subjected to elevated temperatures, chemical attack and high pressure. So selecting the appropriate glass substrate is critical in order to ensure safety even in the harshest of environmental conditions.

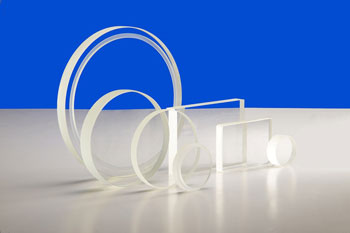

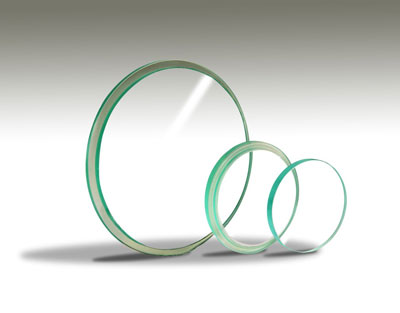

The sight glass is a disc held between two metal frames which are bolted, clamped, or fused to the frame. The glass itself can be strengthened (heat tempered) for additional durability, and may be coated for enhanced visibility and corrosion resistance. Fused sight glass is also called mechanically pre-stressed glass, because the glass is strengthened by compression of the metal ring. Heat is applied to a glass disc and its surrounding steel ring, causing a fusion of the materials. As the steel cools, it contracts, compressing the glass and making it resistant to tension. Because glass typically breaks under tension, mechanically pre-stressed glass is unlikely to break and endanger workers.

Typically, a sight glass window is made from a thick borosilicate glass such as SCHOTT Borofloat®, an optically clear, very versatile glass that has excellent light transmission, thermal and chemical properties. Borofloat® outperforms soda lime glass due to its low iron content resulting in exceptional UV and light transmission. For less critical applications, soda lime glass may be used. For the most extreme applications, one should choose quartz or sapphire.

When determining glass thickness and diameter/area of the vessel pressure must be taken into consideration. The sum of SCHOTT Borofloat® properties makes it unique for sight glass applications as it has outstanding thermal resistance, it is chemically durable, has excellent mechanical strength and exceptionally high transparency all of which are selection criteria.

When selecting a sight glass substrate the following characteristics of the glass should be considered:

- Transparency

- Thermal Shock

- Corrosion

- Abrasion

- Pressure

- Impact

For operating conditions of up to 500°F, borosilicate glass should be selected. For temperatures over 500°F, such as high temperature steam, quartz or sapphire would be the recommended substrate. Applications requiring a temperature range of 300°F or less may use soda lime glass.

Typical sizes are up to 8” in diameter and ¾” thick, but can be provided as large as 25” in diameter and up to 1” thick if required.

Abrisa Technologies can customize sight glass for unique installation requirement s by providing stepped, flanged, or beveled or polished edges, Grooves can also be added to accommodate mounting. The rectangles/rounds can also be tempered For easy readability in less than desirable environments, oleophobic/hydrophobic coating (CleanVue PRO™) improves visibility, and gaskets aid with mounting and sealing.

Value-Added Options

Easy-to-Clean Oleo/Hydrophobics

Gaskets for Environmental Seals

Common Edge & Installation Treatments

Grooved Edge

Stepped Edge

Beveled or Polished Edge

Comparative Information for Sight Glass Selection

Sight glass windows can be found in the following industries:

Sight glass windows can be found in the following industries:

- Chemical & Petrochemical

- Pharmaceutical & Biotech

- Food & Beverage

- Oil & Gas

- Utility Industry

- Bio-gas & Bio-fuels

- Wastewater Treatment