Sensor & Scanner Coatings

Optical and image sensor use is on the rise with growing applications in industrial 3D metrology, machine vision, automotive obstacle avoidance, security and surveillance, document and 3D scanning, gesture recognition and other digital imaging applications. Abrisa Technologies’ rare combination of performance coating design and volume glass fabrication offers the OEM an opportunity for a Total Solution for their sensor and scanning windows; an excellent balance of optical coating performance and economies of scale.

Abrisa Technologies now offers a selection of coated solutions for both laser line and broad spectral ranges from the visible to SWIR, with large angle-of-incidence accommodation and high throughput. Spectrally selective coatings for use outdoors or with discreet diode emitters are also available.

Damage Resistant and “Tough” Environment Solutions

Many applications for sensors and scanners are industrial or for field use where uptime and reduced product maintenance are not just desirable, but a necessity. Abrisa Technologies offers coated sensor and scanner window solutions for these “tough” use environments as well, whether they be outdoors in sunlight, on the seas or on the road, installed in a hot and humid factory, have high traffic interface contact or constant exposure to dirt and other contaminants.

Specifications

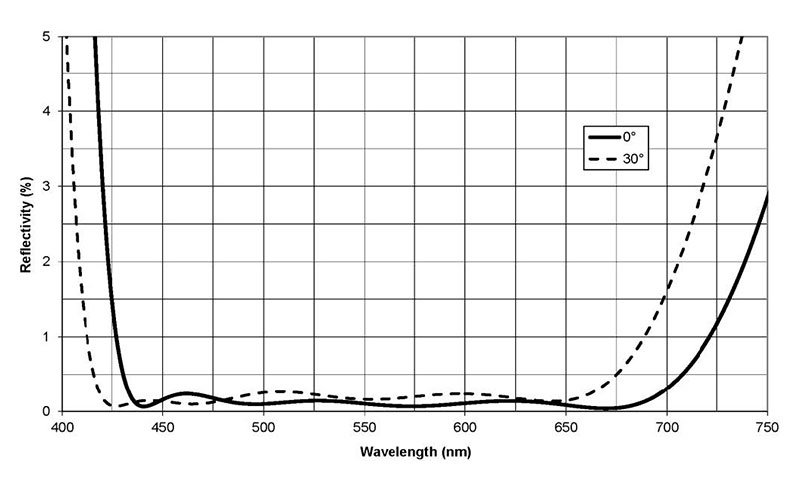

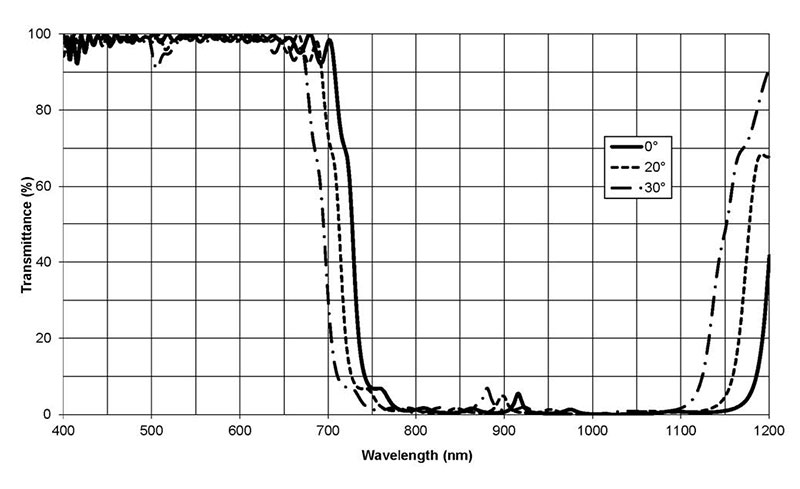

AR Coating Visible

G1

- Visible AR coating for full color LCD & OLED Displays

- Ravg < 0.5% (AOI = 0-30º) 425-675nm

- Also available with oleo/hydrophobic properties

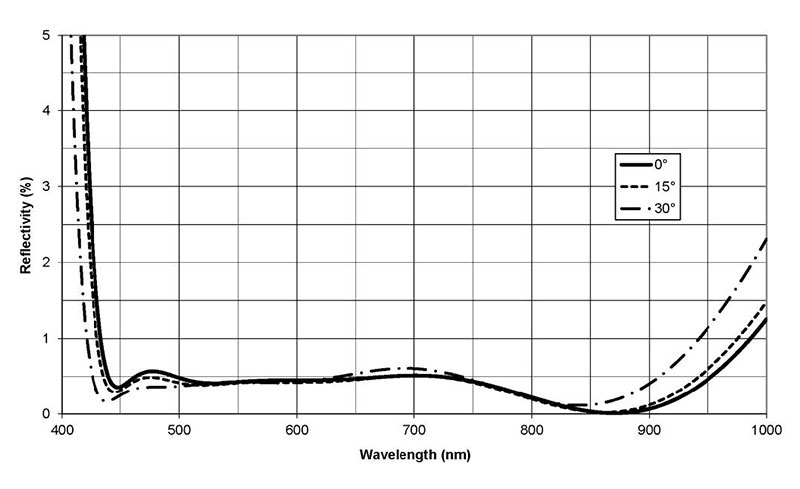

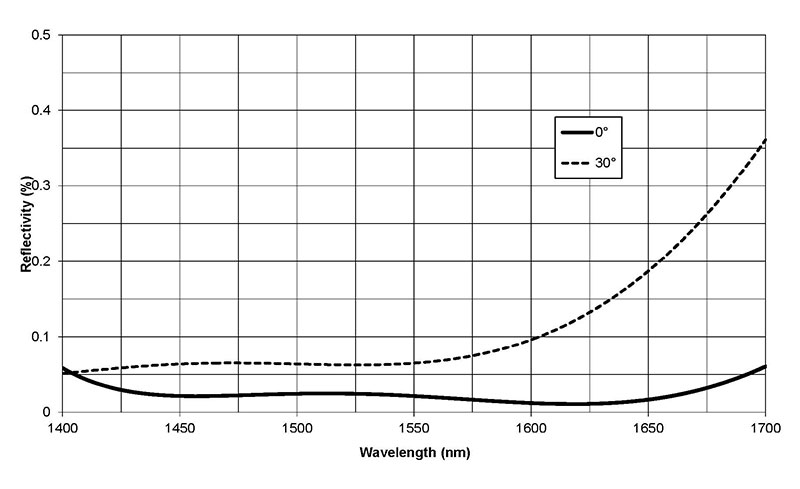

AR Coating 425 – 900nm Blue Bias

G3

- VIS-NIR coating to enhance blue responsivity

- Ravg < 1.25%/1.5% 425-850nm (AOI = 0/30º)

- Also available with oleo/hydrophobic properties

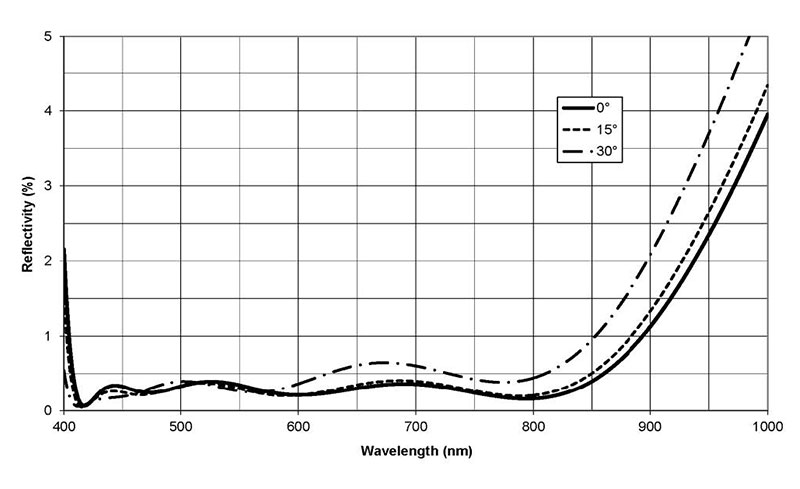

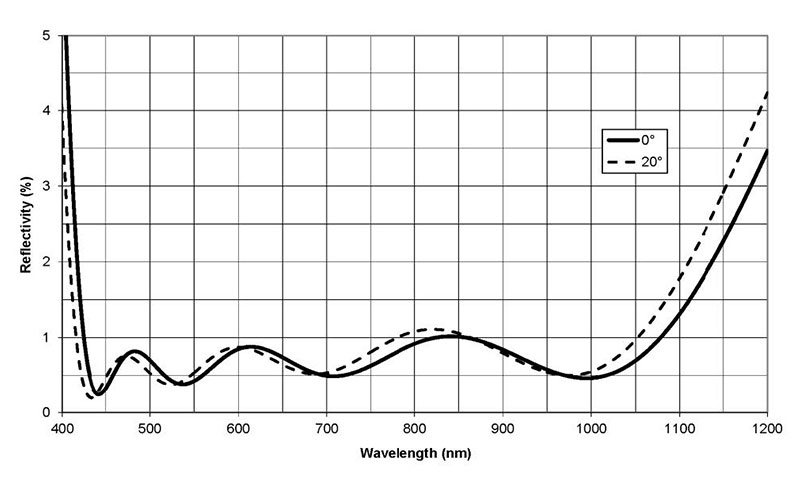

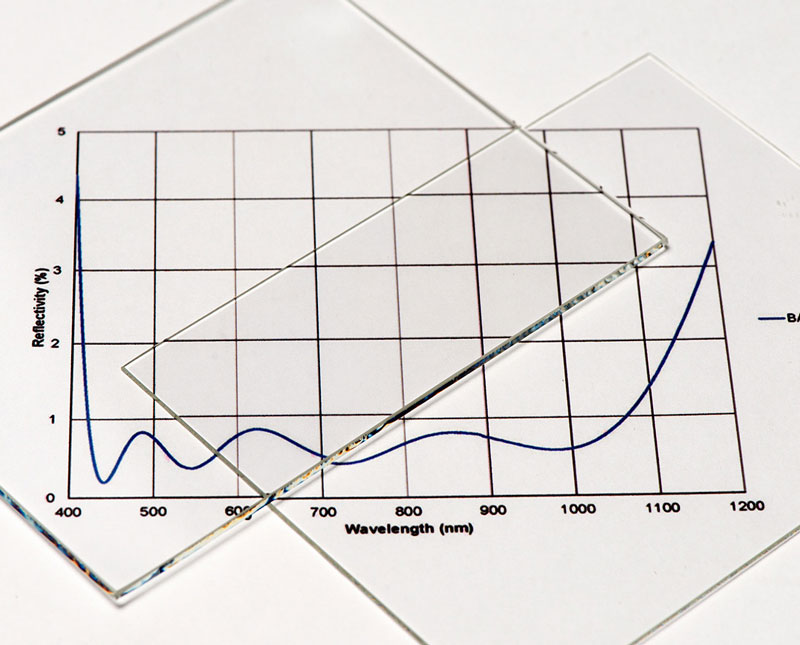

AR Coating 425 – 1050nm

G5

- Expanded range VIS-NIR AR coating

- Ravg < 1.0% 425-1050nm (AOI = 0-20º)

- Accommodates diode emitter sources (730-980nm)

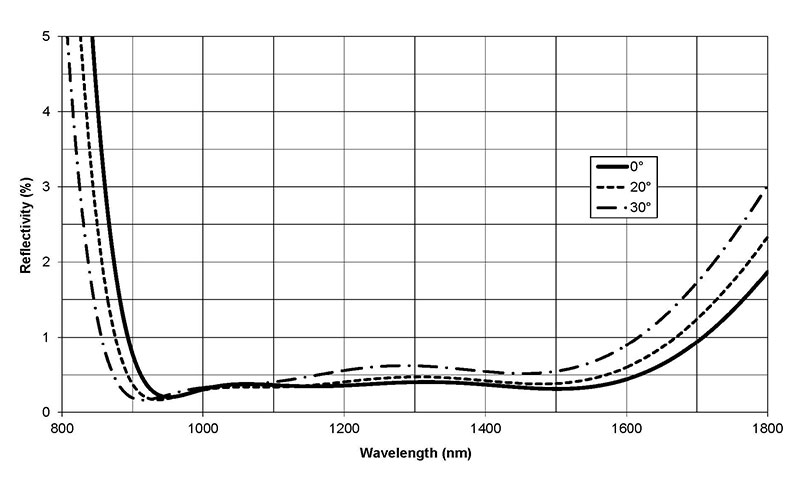

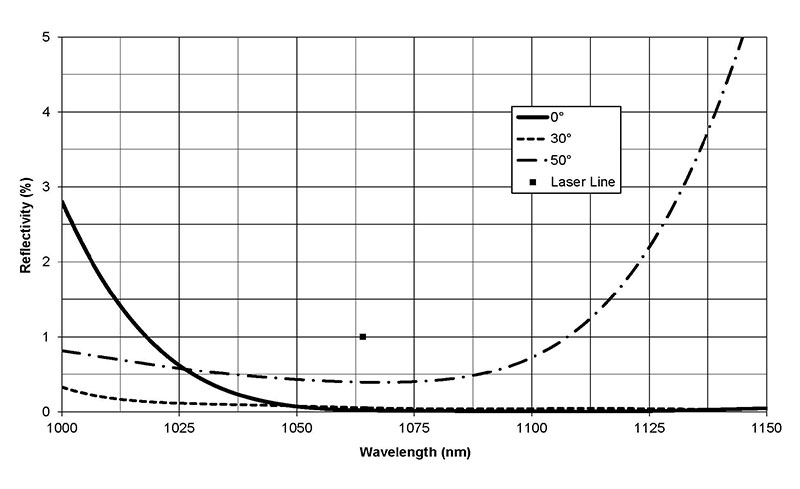

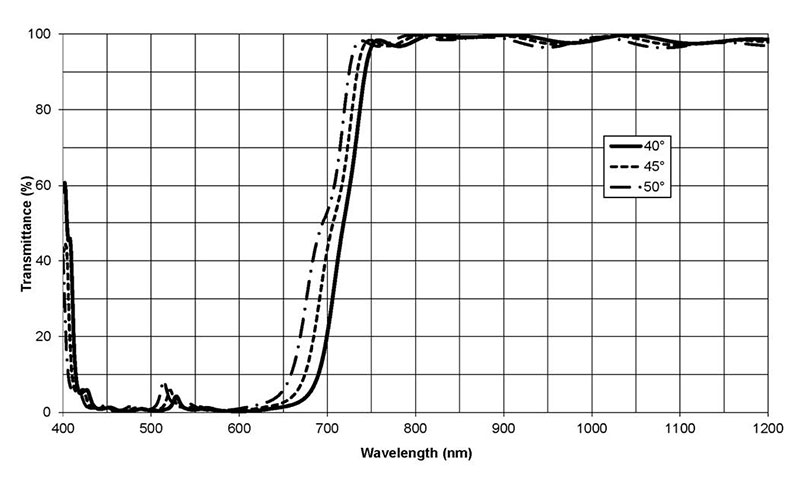

AR Coating Laser Line

G7

- Wide angle coating for 3D metrology, printing, scanning

- Ravg < 0.5% (0-50º) at single wavelength

- Custom designs for diode & laser wavelengths