Soda-Lime & Low Iron Glass

Soda-lime glass, also called soda-lime-silica glass, is the most prevalent type of glass, used for windowpanes, and glass containers (bottles and jars) for beverages, food, and some commodity items. Glass bakeware is often made of tempered soda-lime glass.

Abrisa Technologies can provide custom fabrication and thin film coating of a wide selection of soda-lime float glass. Soda-lime glass can be chemically strengthened to increase mechanical strength or heat strengthened/tempered to increase thermal shock resistance and mechanical strength. The substrates can be machined, optically coated, chemically etched, sandblasted, colored, or laminated.

Soda-Lime sheet glass is made by a floating molten glass on a bed of molten tin; this method gives the sheet uniform thickness and very flat surfaces. Soda-lime is the base material for most clear, colored, and patterned glass types. Soda-Lime glass can be used in a wide range of applications.

Abrisa Technologies can supply the following soda-lime glass substrate material:

- Clear & Tinted – provides high light transmission, can be AR coated for super high transmission, can be chemically strengthened, and has good flatness and no green tint.

- Grey Glass – Grey class is a tinted soda lime glass that is primarily used to restrict or reduce light transmission.

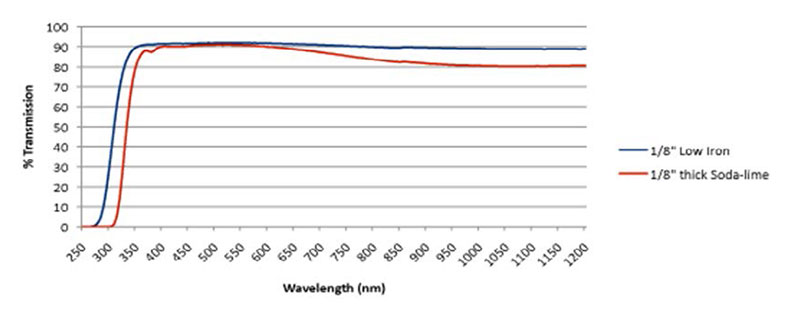

- Low Iron Soda-Lime – provides high light transmission, can be AR coated for super high transmission, can be chemically strengthened, and has good flatness and no green tint.

- Anti-Glare Reducing Etched Soda-Lime – provides glare reduction, has high resolution, superior durability, and anti-Newton ring.

- Patterned Glass for Light Control – can be fabricated into virtually any shape, drilled, sandblasted, screen printed, polished, UV coated, dichroic coated, heat tempered, and more.

- Low Emissivity (Low E) – provides a higher window U-Value, increased insulation performance, energy savings, and decreases color fade by blocking UV light.

- Heat Absorbing Float Glass – Absorbs IR.

Low Iron Soda-Lime Glass

Features

- Higher light transmission

- Can be AR coated for super high transmission

- Can be chemically strengthened

- Good flatness

- No green tint

Applications

- Port projection

- Display

- Lighting

- Optical

- Architectural