Most people are familiar with conventional mirrors that we see and use every day, from the bathroom mirror, a hand held mirror, or a car’s rearview mirror. These mirrors use glass as a protective surface and have the mirror coating, commonly referred to as “silvering”, on the back side, or “second surface”. The exposed glass helps protect the mirror coating underneath from scratching or degradation due to environmental factors such as weather, fingerprints, and dust.

Most people are familiar with conventional mirrors that we see and use every day, from the bathroom mirror, a hand held mirror, or a car’s rearview mirror. These mirrors use glass as a protective surface and have the mirror coating, commonly referred to as “silvering”, on the back side, or “second surface”. The exposed glass helps protect the mirror coating underneath from scratching or degradation due to environmental factors such as weather, fingerprints, and dust.

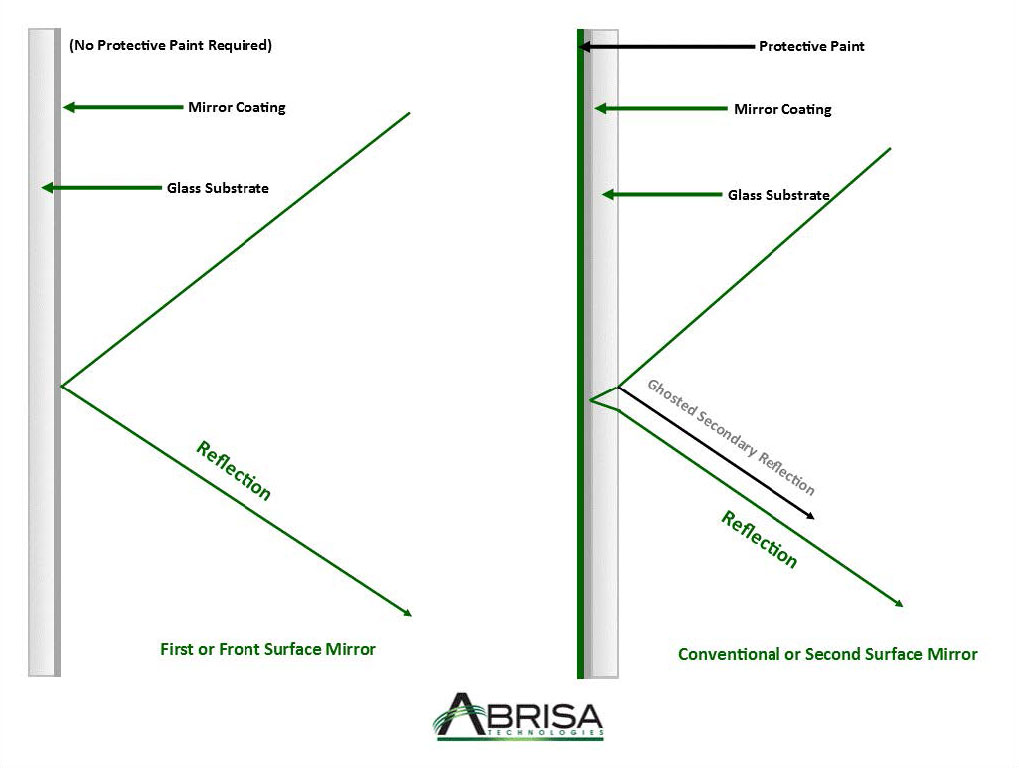

In high precision applications, second surface mirrors have some very distinct disadvantages. Light traveling through the glass to strike the reflective material on the backside or second surface creates a refracted or bent image as well as some loss of energy, essentially dimming and distorting the reflection. A faint secondary reflection is also created from light striking the front of the glass. This secondary image is referred to as a “ghost image” or “ghosting effect”.

In order to provide a clear reflection without “ghosting” a front or first surface mirror is an excellent solution. The mirror has the reflective surface (i.e.coating) on the viewing side, or front surface of the glass which faces the incident light. The mirror coating is generally an enhanced aluminum, protected gold, or silver. Other precious and non-precious metals such as titanium, inconel, chromium, copper, hafnium, tantalum, tungsten, germanium, and molybdenum can be used depending upon the particular application and performance requirements. The light reflects directly off the mirror coating without passing through the glass substrate, both eliminating the ghost image and increasing the quality and intensity of the reflection. While a second surface mirror will typically reflect around 80 to 85% of the incoming light, a first surface mirror typically reflects 94 to 99%.

First Surface mirrors are primarily used for projecting clear sharp images in applications such as:

First Surface mirrors are primarily used for projecting clear sharp images in applications such as:

- Flight Simulation

- 3D Printers

- Optical Imaging & Scanning

- Digital Signage

- Rear Projection TV

- 3D Entertainment

- Astronomy/Telescopes

- Gaming

A first surface mirror is the optimal choice when clarity and single image reflection are most important. The loss of contrast and image distortion caused by light passing through the glass in a traditional mirror design is undesirable in high precision applications like those listed above. While a first surface mirror also typically uses a much higher quality coating than a standard mirror, it is really the first surface design that minimizes energy loss and distortion.