Low Iron Soda-Lime Glass

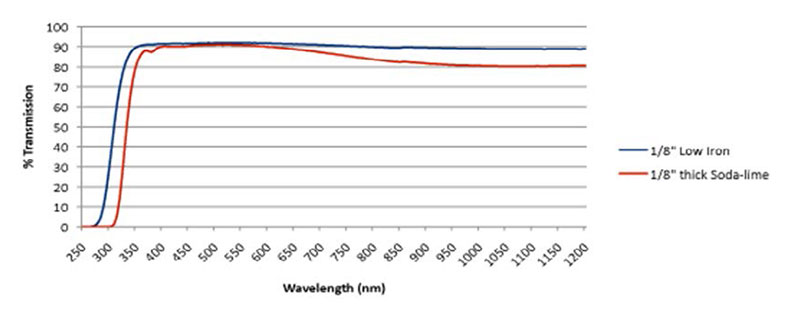

Low iron soda lime is created by using high quality grades of silica sand that are virtually free of iron oxides. This results in a transparent, “water white” glass that has higher transmission characteristics compared to normal soda lime. The difference is usually 2-3% at thicknesses 10mm and up to 8% greater transmission for thicker low iron glass. Even higher transmission (up to 98-99% total transmission) can be achieved by specifying an anti-reflective thin film coating. (Refer to our Thin Film Coating Brochure).

Features

- Higher light transmission

- Can be AR coated for super high transmission

- Can be chemically strengthened

- Good flatness

- No green tint

Applications

- Port projection

- Display

- Lighting

- Optical

- Architectural

Dimensions

Thicknesses

1mm – 12mm thick

Sizes

Up to 130" x 96" (3302 x 2438.4mm)

Physical Properties

Density

2530 kg/m3

(158 lb/ft3)

Modulus of Elasticity

7.2 x 1010 Pa

(10.4 x 106 psi)

Modulus of Rigidity

3.0 x 1010 Pa

(4.3 x 106 psi)

Bulk Modulus

4.3 x 1010 Pa

(6.18 x 106 psi)

Poisson’s Ration

0.23

Specific Gravity

2.53

Coefficient of Thermal Stress

0.62 mPa/°C

(50 psi/°F)

Thermal Conductivity

0.937 W.m/m2°C

(6.5 btu.in/hr.°F.ft2)

Specific Heat

0.21

Coefficient of Linear Expansion

8.9 x 10-6 strain/°C

(4.9 x 10-6 strain/°F)

Hardness (Moh’s Scale)

5 to 6

Refractive Index (Sodium D line)

1.523

(1 μm)

1.511

(2 μm)

1.499

Softening Point

726 °C

1340 °F

Annealing Point

546 °C

1015 °F

Strain Point

514 °C

957 °F

Emissivity (Hemispherical) at 75°F

0.84